How to reduce custom plastic mold-making time?

How to find high-quality mold manufacturing companies in China?

There are many companies and custom plastic mold-making units that are capable of operating and have had many impressive results. Let’s find out in the most objective way in the article below.

The general capacity of custom plastic mold-making companies in China

In general, the capacity of mold companies in China is currently meeting the domestic and international simple processing needs. However, there are still many limitations in terms of production level and technological lines, equipment and machinery.

Aware of the importance of investment in facilities, many mold companies are increasingly focusing on upgrading and applying technology, importing machinery, and using modern design software. Thereby optimizing production time, improving custom plastic mold-making quality, and increasing attractiveness in the market thanks to competitive prices.

The ability to make molds with high technical requirements

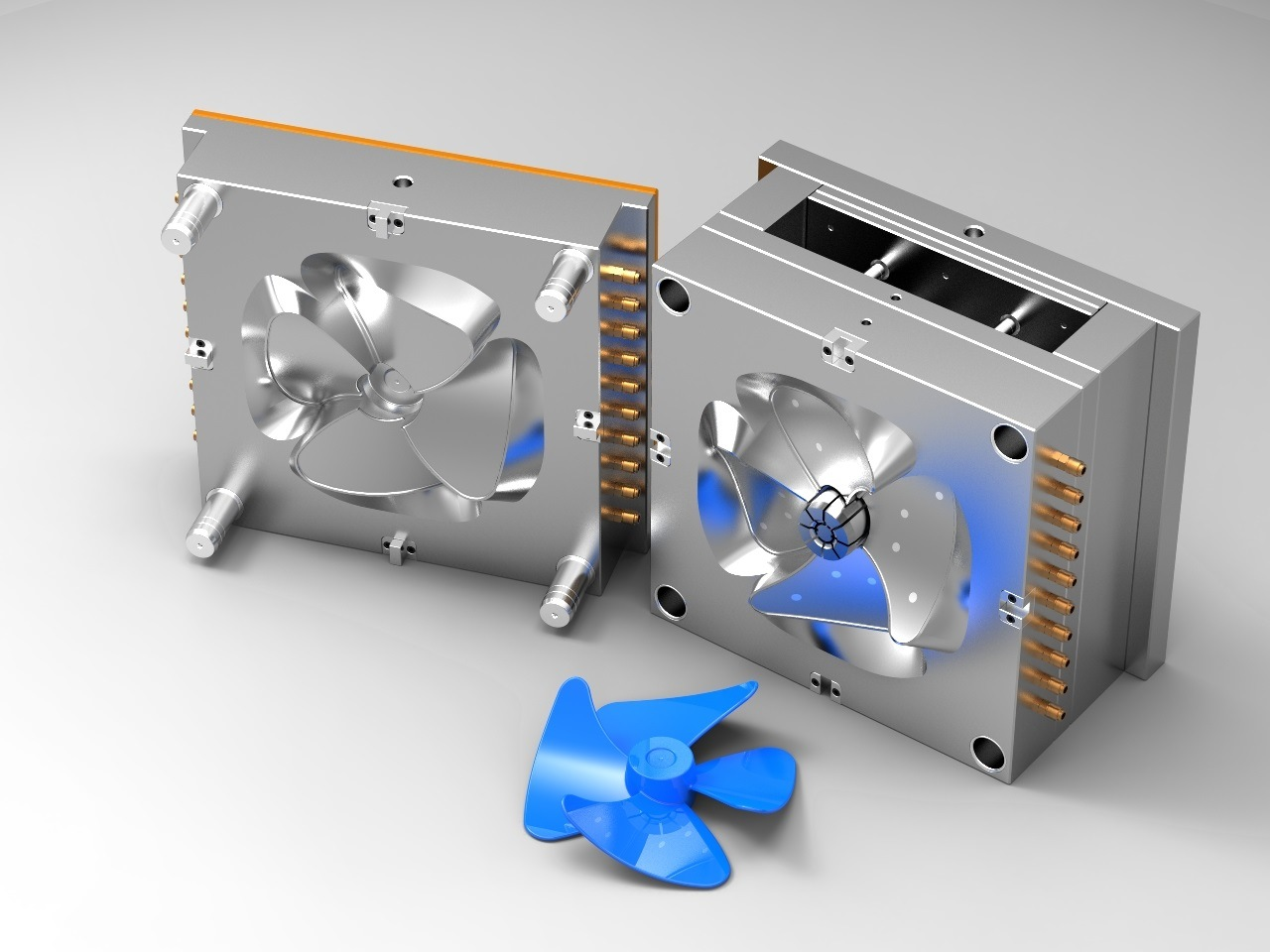

A finished mold product requires a lot of details, the more complex the mold, the more complex detail require, and the technical requirements are high. The processing of details is not an easy job, it is necessary to have the presence of modern machinery and equipment, skilled workers, and input materials to meet the quality requirements.

Conduct strict quality monitoring and supervision throughout the entire processing process. A custom plastic mold-making company, if it performs well-processing orders with high technical requirements and complexities, will be able to export goods and fulfill international orders, bringing great value to the business.

Export molds, mold details to foreign countries

Currently, in China, there are many companies and mold manufacturing units, but only a few companies manufacture high-quality molds with high processing levels to meet the needs of mold export. Manufacture molds abroad, especially in developed countries with strict product requirements such as the UK, Japan, the US.

In order to achieve high-quality mold processing, custom plastic mold-making details with complex technical requirements, the processing unit needs to have a good processing capacity, equivalent to the processing capacity of foreign companies.

How do companies develop custom plastic mold making?

High-quality mold manufacturing companies often attract customers who are FDI enterprises in export processing zones. These are usually large, potential customers, but often require strict mold product quality. Some target FDI enterprises include Samsung, Canon, Toyota, Honda, and Panasonic.

Technological products such as computers, printers, phones, etc. need to use plastic parts and components with extreme accuracy. Therefore, the custom plastic mold making must meet the technical requirements to produce the desired product.

How companies can fulfill the requirements of customers?

In fact, in order to meet the increasing requirements of domestic and international demand, mold manufacturing companies need to constantly innovate, create, invest and improve the system of equipment and machinery, improve the quality of human resources, thereby enhancing the capacity and position of the company.

Plastic injection molding machines are commonly used in injection molding technology lines. The machine has the role of keeping the mold closed while pushing the molten plastic by injection pressure into the custom plastic mold-making core to fill the mold cavity and open the mold after the product is cooled. The formed product will then be pushed out through the plastic injection mold system.

Construction of plastic injection molding machine

On the market today, there are many different types of injection molding machines, depending on the financial situation of the business and the characteristics of the company’s production activities that choose different types of injection molding machines.

Basically, a plastic injection molding machine consists of 5 main parts with the following functions: Injection molding support system:

It is a particularly important system during the operation of the custom plastic mold-making machine. Because the injection molding support system includes electrical, hydraulic, cooling, and body systems.

Mold system:

Perform the function of pressing and shaping the product.

Control custom plastic mold making system:

It is the control panel of plastic injection indicators. In which, the custom plastic mold making system is the part that can be disassembled, the remaining parts are fixed. Plastic injection molding machine will allow installing 2 plate mold or 3 plate mold easily based on product characteristics and production purpose.

Using plastic injection molding machine

Before using a plastic injection molding machine, it is necessary to read the documentation to master the operating skills of the injection molding machine, the operations on the machine to ensure efficiency, safety, and the ability to handle situations arising on the machine.

Master the operation of opening – shutting down safely

Turning off and opening the machine safely is the first mandatory requirement in operating the plastic injection machine.

Turning off and opening the machine safely is extremely important, affecting as well as the operation process as well as the life of the machine.

Plastic injection molding machine control panel

Know how to safely mount the mold on the machine

As mentioned, the custom plastic mold-making part is a separate part from the machine. Furthermore, the process of attaching the mold to the machine is a mandatory process.

Mold clamp force adjustment

After the mold fix the next step is to adjust the clamping force of the mold. Too much clamping force will cause problems such as:

- Energy Consumption

- Machine Volume

- Causing Wear of the Mold and Machine

- Similarly, reducing the exhaust of the mold

- Prolong the Pressing Cycle

Steps to prepare raw plastic for custom plastic mold making

The sequence of custom plastic mold making preparation steps includes:

- Step 1: Take a sample to check if it is correct and compare it with the information on the package.

- Step 2: Check plastic screening, remove impurities mixed in plastic.

- Step 3: Bring the plastic to dry to the specified temperature and time, to ensure that the plastic products are not defective.

- Step 4: Put into the press to join the liquefaction of plastic injection into the mold

How liquefaction of raw plastic can be done?

The drying and liquefaction of raw plastic are done automatically by machines. We are a custom plastic mold-making company that owns a fully automated production line.

The automatic operation cycle saves both time and maximum manpower. The plastic injection molding machine documentation is given by the engineers who have the expertise and thorough knowledge of the machine.