Injection Mold Making

Want to know more about our Service of Injection Mold Making?

Then Click the pictures below to Learn More About the Molds We Built:

All Services

Why Choose TIP-TOP?

(1) Tip-Top is a Reliable One-Stop-Shop for your Injection Molds and Plastic molded parts. We have fast response rate, competitive price, a professional work team, a strong quality control system, and on-time delivery, which can make you spend the least effort and money in getting your most satisfied injection molds and plastic molded parts.

(2) Tip-Top Molds is mainly engaged in Injection Mold Design, Injection Mold Making, and Plastic Part Molding, including both prototype and high-volume production tools.

(3) Highly efficient and skilled team of design and toolmakers of Tip-Top Molds can guarantee top-quality molds and short delivery time. We submit progress reports along with weekly digital pictures so that our valued customers know the status of their molds throughout the tool-building process. Quality engineers and technicians constantly monitor all segments of our operations from design to final mold delivery.

(4) Tip-Top has already cooperated with over 40 overseas customers and exported over 1500 sets of injection molds. We take strong pride in the fact that most of our customers have been with us since we started until today.

(5) Our company has been ISO 9001 certified since 2006.

What is Plastic Injection Mold?

A plastic injection mold is a specialized kind of processing tool specifically used in the process of plastic injection molding. With plastic materials, injection molds could be used to produce plastic parts in different shapes and they are usually used in mass production. In addition, plastic injection molds are constructed using special tool steel or aluminum with exceptional tensile strength, durability, thermal characteristics, and material density.

What is the Process of making a Plastic Injection Mold?

The process of mold making can be summarized and simplified in the following steps:

Design For Manufacturability (DFM) →3D CAD model of the part→ Sometimes prototype molds are built and tested → Production Mold Building → Mold Trial and review the quality and workmanship.

What areas is Plastic Injection Mold often applied to?

The applications of plastic injection molds can be observed in almost anything and everything can be made of plastic. The industry of plastic injection mold has evolved over the years from producing combs and buttons to producing a vast array of products for many industries

Here are some examples of the common industries:

- Automotive Industry

- Household Appliance Industry

- Medical Industry

- Aerospace Industry

- Consumer Products Industry

- Toys Industry

- Packaging Industry

- Construction Industry

- Cellular Industry

- Cosmetic Industry, etc

What can Tip-Top do for you?

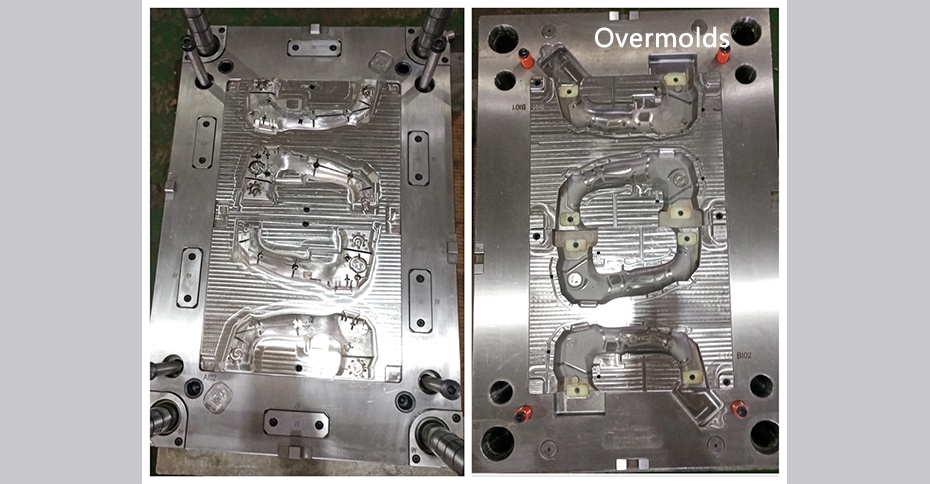

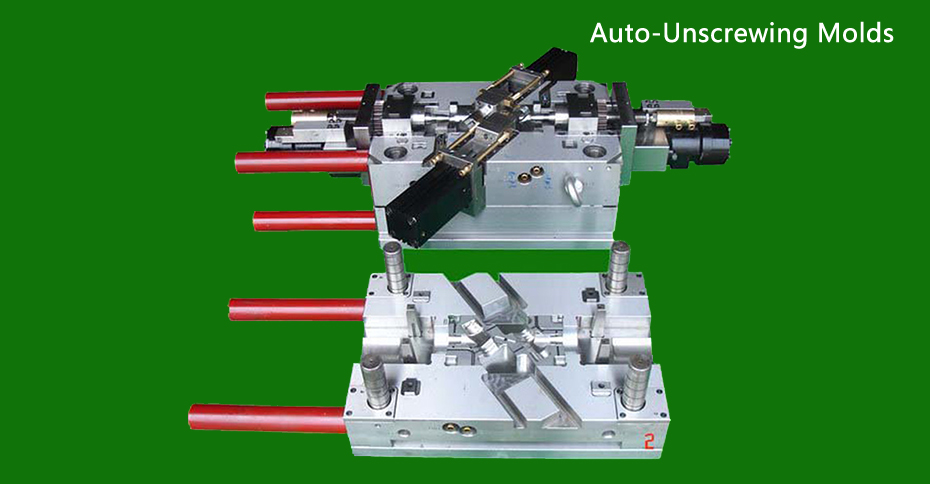

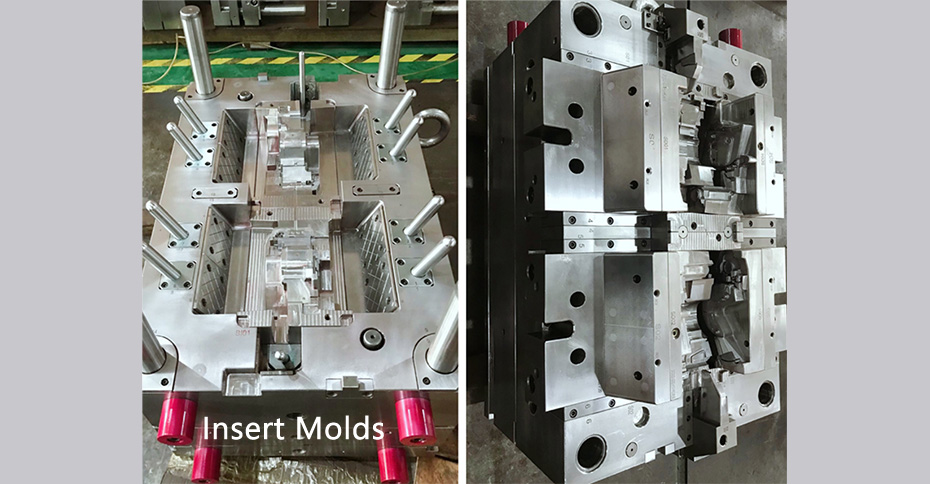

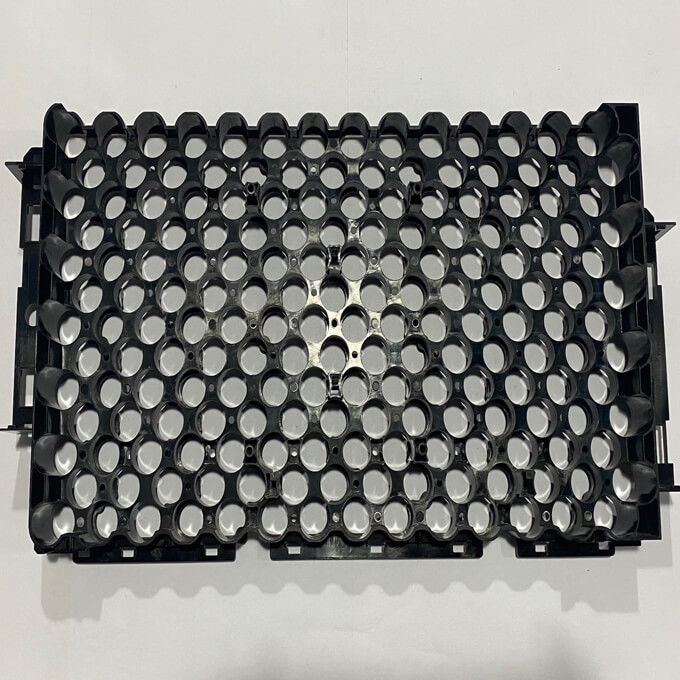

Tip-Top Molds produces a wide range of injection molds from single cavity molds to multi-cavity molds. Our mold types include low, middle, and High Volume Production Tool. We are good at making standard injection molds with side actions and lifters, Hot Runner Injection Molds, Unscrewing Injection Molds, 2-Shot molds or 2K moulds, Overmolds, Collapsible-Insert Injection Molds, Gas-Assisted Injection Molds, and 3-Plate Molds, etc.

Equipped with three CNC Machining Centres as well as a HAAS’s (VM-2) and Beijing Jingdiao’s (600V) high-speed CNC Machining Centres, six EDM Machines and one 2-head of EDM Machine, three Precision Grinding Machines and one Water Grinding Machine, Spiral Air Compressing Machine, five Overhead Cranes and one 2-head Overhead Crane, and Smart Water Test Machine, etc., Tip-Top Molds can reach an annual output of over 150 sets of plastic production molds and has already built over 1500 sets of molds which were exported to overseas customers, of which the heaviest weight was 14 tons and the lightest weight was 20kg. The smallest size of a precision mold was 150x150x150mm.

Our molds are constructed with the DME and Hasco standards precisely. We can provide any required brands of mold components such as DME, HASCO, INCOE, EWIKON, YUDO, MOLDMASTER, PROGRESSIVE, MERKLE, PARKER, LKM, ASSAB, and so on.

How is our Plastic Injection Mold Design?

Being more and more experienced in the plastic injection mold industry, we know that a high-quality part comes from a high-quality mold and a good part design. Comprehensive mold design is the key to manufacturing a high-performance mold.

The key to satisfactory and successful mold making is that QUALITY must begin with mold design capability. At Tip-Top Molds, we have both a skilled team and professional ability to ensure that our designs can achieve your high expectations.

Tip-Top Molds is able to design molds according to customer’s product designs, 2D and/or 3D models, or drawings with specifications.

Our mold design capability includes:

- DFM

- Mold Flow Analysis

- Optimization

- Full 2D & 3D Mold Design

- Unique designs through collaboration with customers

We design our molds according to our customer’s requirements.

With more than 17 years of experience combined in the machinery manufacturing and plastics industry, we have expertise in anticipating the quality of the mold and potential problems or risks of mold-making at the earliest stage. And then we are able to optimize the mold design with our customers to eliminate those risks before the start of mold production.

The engineering software is used at Tip-Top Molds:

- Data format: .PRT, .X_T, .STP, .STEP, .IGS, .DWG, .DXF, .PDF, etc.

Chinese Plastic Injection Mold Manufacturer

We have over 17 years of experience in Injection Mold Design,Injection Mold Making and Plastic Injection Molding, including Overmolds, Auto-Unscrewing Molds, Insert Molds, 2-Shot Molds/2K Moulds, and Other Injection Molds……