High volume plastic molds on CNC machines: Best Guide 2021

CNC machines are currently a popular type of mechanical processing machine in mechanical workshops in particular and manufacturing facilities in general. Because of the advantages such as increasing product accuracy, shortening machining time, and saving costs. Therefore, many companies are looking to buy high-volume plastic molds suitable for their needs and high processing efficiency.

Hence, we want to bring you quality products at extremely competitive prices.

1. Experience in buying quality and efficient CNC machines

Companies should refer to the experience of buying high-volume plastic molds from experts. To choose the high-quality machine with the best price:

Based on actual processing needs

Enterprises should base on the needs of detailed processing that choose the appropriate machine. Buying a 3-axis CNC machine to process small, simple parts is a good idea. 4-axis, 5-axis CNC machines are suitable for performing highly complex parts. The bed machine is suitable for large and heavy workpieces.

For hard materials or high precision, a large-capacity, multi-axis machine is required.

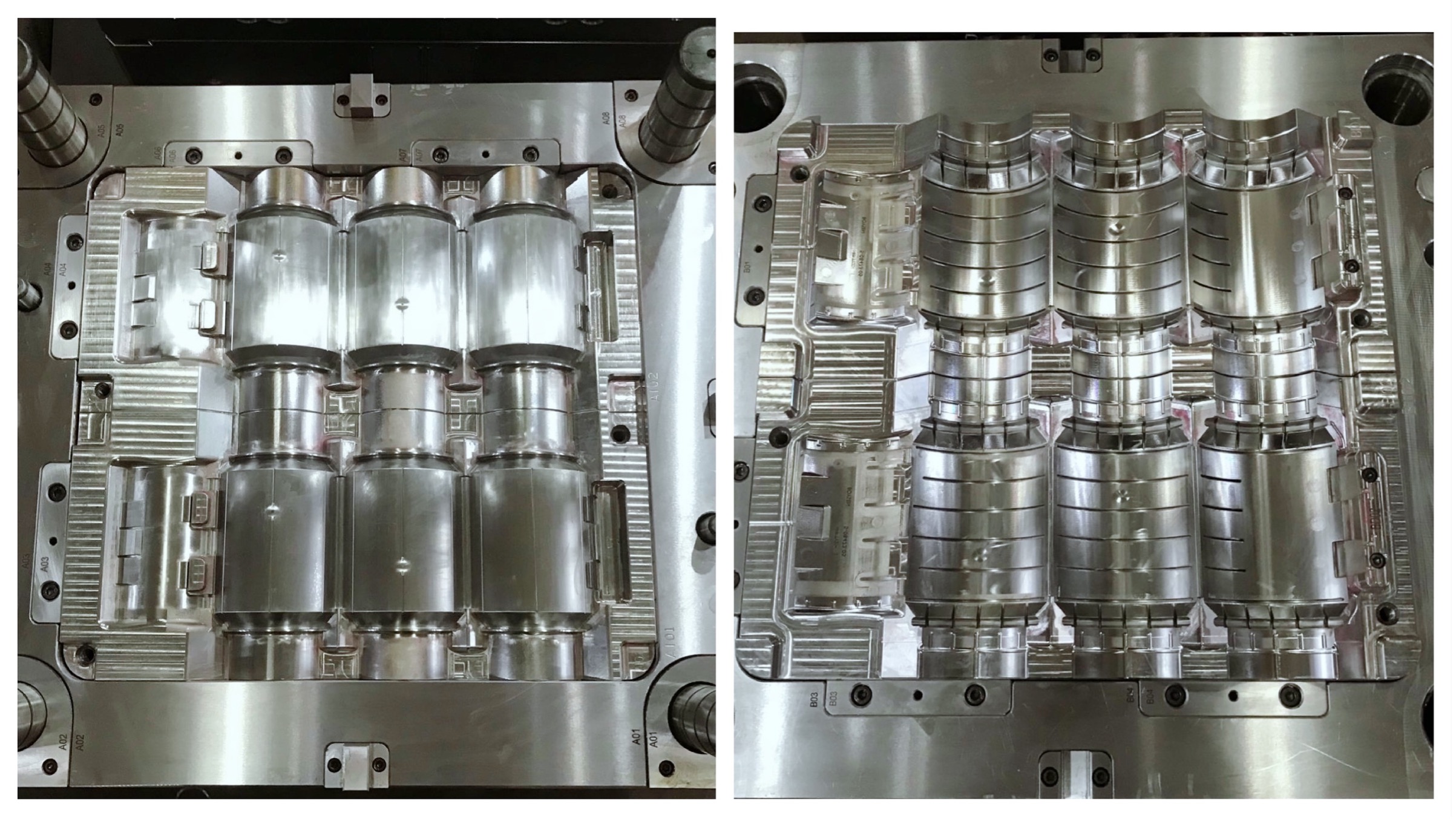

High volume plastic molds on CNC machines

Market assessment and actual supply situation

Businesses should find out information about a variety of machines from many different reputable brands. About parameters, machining ability, number of axes, price, then analyze and compare them to choose the right type of machine.

You can also consult information from experienced people who have common the device on high volume plastic molds. See what kind of machine they usually use, how many axes they use. You can ask for a price range for one or more machines, discounts, incentives when buying, etc.

Choose a reputable machine supplier

You should choose to buy machines from high volume plastic molds suppliers in countries with advanced technology such as the:

- The United States

- China

- Japan

Machines here often have higher quality and durability. And there may be attractive discounts and incentives.

Moreover, they have a warranty policy and periodic maintenance. As well as having spare parts to replace when needing to repair and fix machine errors.

Other factors which influence high volume plastic molds

Also to buy high-quality and suitable CNC machines for production processing needs. You need to rely on the following factors:

- The size, shape, and material of the parts to be machined.

- Dimensions of the workspace. Such as the size of the table, knife, chuck.

- Moreover, length, width, height, number of parts are to be machined in one cycle.

- Similarly, tool power, spindle power, and machine efficiency.

- Various types of tool holders are common for the machine such as BBT/CAT/BT/ HSK tool heads.

- Furthermore, compatibility with machine design, programming, and operating software.

- The number of axes of the machine. Depends on the complexity of the parts to be machined

2. Factors affecting the purchase price of high volume plastic molds

CNC machines can significantly improve high-volume plastic molds. Therefore, it is important to buy them from reliable suppliers.

Different models with different functions, structures, and sizes will have different prices. Some factors that directly and indirectly affect the price of a machine are machine features, machine suppliers, machine design, after-sales service, transportation, etc.

- Larger machines with larger X, Y, and Z strokes will be able to process large parts and have higher prices.

- Large machine weight with heavy chassis will add more stability to the machine.

- The spindle with a fast rotation speed increases the product accuracy and the machined surface quality is higher.

- Moreover, the machine table moves at high speed, the processing output at one time will be larger.

- Machine power depends on servo motor, spindle torque, machine power.

- A number of tools and tools change the times of the machine.

- Price also depends on optional parameters such as automatic billet removal system, oil mist collector, bar conveyor, etc.

Besides paying attention to the machine price, enterprises know well the processing needs and choose the type of machine with appropriate features to bring high efficiency. Moreover, you should also choose to buy CNC machines from reputable companies to use the machine for a long time and maximize its performance.

Where can I buy high-quality high-volume plastic molds?

Imported CNC machine is a reputable unit that provides quality high-volume plastic molds with extremely competitive prices today.

Imported CNC machines are currently the distributors of many famous and prestigious CNC machine manufacturers in the world. The products provided by us are 100% new, genuine, with a clear origin. In addition, there are many attractive discounts.

The consulting staff at Imported CNC Machines is well-trained, knowledgeable in the functions, machine parameters, etc. So you can rest assured that you will choose the right machine that best suits your needs.

Advantages of high volume plastic molds

- Help to place the workpiece accurately and save the clamping time.

- The magnetic table does not use electricity, does not need to go into the engine room. It is therefore very safe in the event of a sudden power failure.

Cases in which the word table should be Important

- It is recommended to use a table since processing a series of products. Helps to shorten the installation time of the workpiece.

- When milling, the entire plane of the workpiece has a large size that the vise cannot meet.

- Use in case the workpiece is too thin. Using a vise to clamp may cause warping of the product.

2.2. CNC machine turntable

The turntable is a special type of fixture, mainly common on CNC vertical and horizontal milling machines.

A turntable is a device capable of increasing the number of axes of a machine from 2 or 3 axes to 4 or 5 axes. High-volume plastic molds expand the technological capabilities of the machine.

For non-tilt turntables, it acts as the 4th axis of the machine. With a tilting turntable, it is the 4th and 5th axes called A and B axes.

The turntable is mainly common for machining:

- Shaped surfaces: cam surface, stamping die, press mold, etc.

- Moreover, thread the inner and outer screws.

- Machining gears and multi-blade cutters with straight or helical teeth.

- Cut straight and twisted grooves.

- The inclined surface can be machined.

For multi-axis turntables, it is possible to process many parts at the same time.

- Helps increase the technological capabilities of the machine.

- Increase machining productivity.

- Reduce assembly time, tool control.

- Suitable for batch and block processing.

Summary high volume plastic molds

With many preferential services, we are a reliable high-volume plastic molds company in China.