12 Plastic Injection Molding Tips Every Beginner Should Learn in 2021

List of factors to be considered for plastic injection molding

Following are some important factors to be considered for plastic injection molding:

1. High productivity/efficiency – fast production

There are several basic reasons why injection molding of plastic parts is considered the most acceptable and effective type of injection molding. The process itself is quite fast compared to other methods, and high productivity makes it even more efficient and cost-effective.

The speed of the process of course depends on the complexity and size of the mold, but the interval between each cycle is only about 15-120 seconds. By reducing the duration of the molding process cycles, this method allows the production of more molds in a short period of time, while increasing profits.

2. An integrated approach to the design of plastic parts

The method of plastic injection molding under pressure can be common to produce both complex parts and uniform. This method also allows you to make millions of identical parts. To optimize and increase the efficiency of high-quality injection molding and maximize the accuracy and quality of the parts themselves, it is necessary to consider the basic design elements and design requirements of the part.

3. Design element in injection molding

The design of the part must be as precise as possible to increase the efficiency of the process. The properly designed part allows you to make the element smoothly and with high accuracy. At the same time, without a detailed and calculated drawing of the part.

You may make big and expensive mistakes to the company regarding plastic injection molding. Industry experts unanimously believe that in any part drawing and mold making, there are basic design/drawing elements that must be considered for the injection molding process to take place correctly.

4. Elements of plastic injection molding

These elements include:

- Wall thickness

- Design of the sides of the mold

- The structural round protrusion on the surface of the part

- Corner transitions

- Welding lines

- Placement of entrances

- Properly placed vents

5. Power in plastic injection molding

The increase in capacity is one of the important factors that must be considered when designing a mold for the manufacture of parts by injection molding. The designer needs to have information on whether the part should be flexible or rigid.

Power in plastic injection molding is to adjust the integrating fasteners/mold plugs or corner fasteners. Understanding the purpose of the part, as well as the environment in which it will be common is also an important nuance.

6. How to maintain balance for mold strength

Finding the balance between the elements of the drawing form will determine the required strength (load, endurance, resistance of the material) and stability (hardness, strength, margin of safety). Another important element is the choice of material.

7. The function of flexibility in injection molding Products

The choice of the appropriate material and color of the product are the two main factors in the manufacture of plastic parts. Given the great variety of both components of plastic injection molding. There are many variations of their combination. Advances in polymers have contributed to the development and invention of new polymers/resins.

8. Polymer selection and working

To ensure the correct choice of polymer, the following elements are important:

- impact strength (resistance)

- tensile strength (tensile load)

- modulus of elasticity/flexibility

- heat absorption and water absorption

Polymers are easy to obtain using a variety of coloring systems, each of which has its own characteristics, advantages, and disadvantages. It is important to use a molding machine that has already been common to produce plastic products from various polymers, especially those that meet FDA, RoHS, and REACH, and NSF standards.

9. How to reduce waste in plastic injection molding?

When choosing a partner for plastic injection molding, you should choose those companies that use green technology in their activities. The latter allows to obtain the highest quality, ensure sustainability, and optimal safety.

During the molding process, there will be excess plastic. When choosing partners, you should focus on those companies that use technologies for processing excess plastic. The most environmentally friendly manufacturers of plastic products use state-of-the-art machines and machines to reduce waste, reduce transportation and packaging costs.

10. Reducing labor costs

In the production of plastic products, labor costs are usually low compared to other ways. Foundry equipment usually works with a stand-alone, automatic tool that allows you to optimize processes and establish uninterrupted production.

In plastic injection molding which it requires minimal control. And the ability to produce parts at a fairly high level with a high volume of production contributes to the economy and efficiency of the process.

11. The Relationship of plastic injection molding with 3d printing

Injection molding and 3D printing are popular manufacturing processes for the manufacture of plastic parts of varying complexity. Although there is a large selection of plastics and thermoplastic materials on the market that are perfect for any part in any process.

There are situations of plastic injection molding where we choose either injection molding or 3D printing. This is what our article is about. To determine which technology to choose for your production, it is necessary to understand the advantages and disadvantages of both methods.

12. Molding of plastic parts under pressure

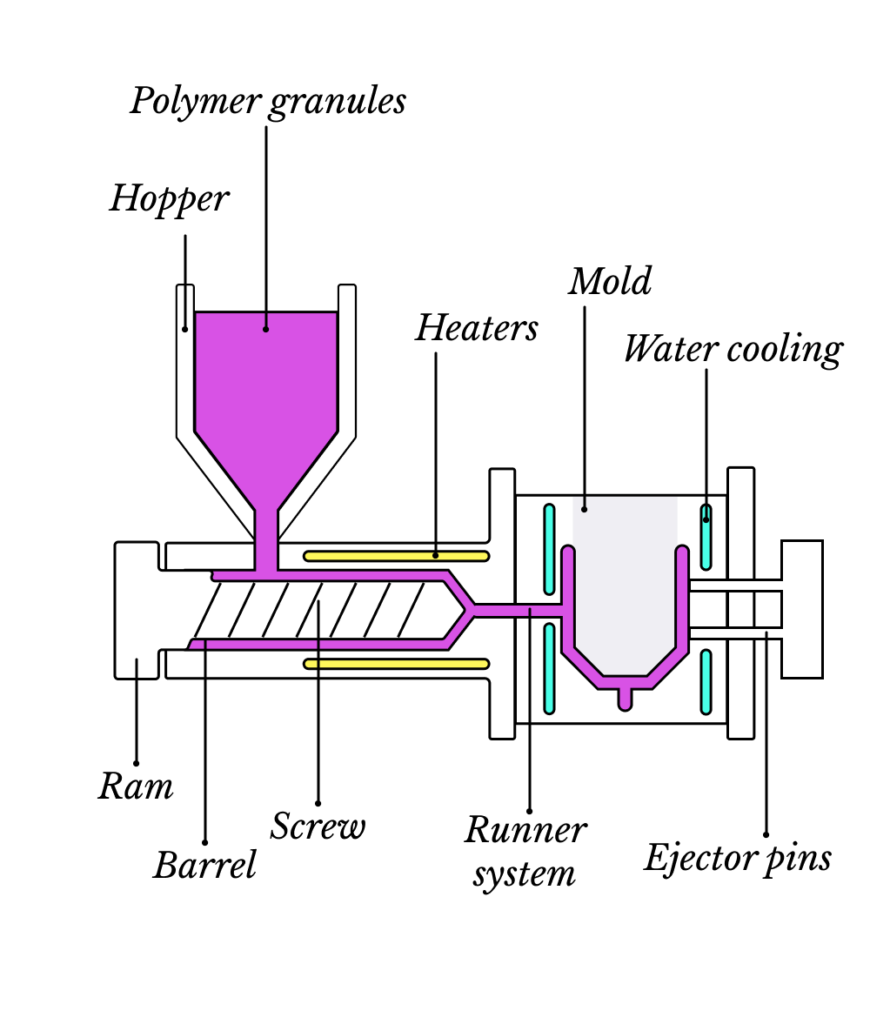

Injection molding is a rapid process that is based on the injection of molten plastic or other molding material into a prefabricated mold.

List of reasons to choose plastic injection molding

Following are some of the points regarding plastic injection molding based on which you can choose plastic injection molding

1. The Importance of cost in plastic injection molding

After the manufacturing of the mold, the production of the part is simple. The molten material comes into the mold under high pressure.

Injection molding of plastics allows the most efficient use of raw materials, so it leaves virtually no waste.

2. Production quality aspect in plastic injection molding

Every millimeter of the mold fills with material as much as possible to prevent air bubbles or other design defects.

Moreover, it does not require additional actions, e.g., suturing or assembly. The work quality is very high, and the result is durable.

So you can get more than one part in one press. This, in turn, speeds up the production of plastic injection molding. Thus, in a day you can make hundreds of thousands of parts and easily sort your products by batches.