What Products Are Made from Injection Molding?

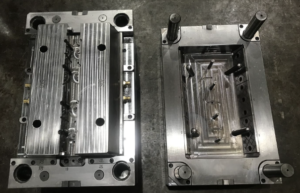

What are plastic injection molds?

What products are made from injection molding? Many injection molding machines are sold in the global market every year, which work with special molds (molding molds, forming equipment).

A mold is a metal device good to use for the production of plastic products by injection molding. They are good to use for mass production. Production should be supervised by experienced engineers who will develop design documentation for the manufactured product, as well as the device itself.

Let’s look at each option:

The application of the technology involves several stages

Initially, the matrix with the powder is exposed to high temperatures until it becomes plastic. What products are made from injection molding? Further, a special punch puts pressure on the plastic, due to which it acquires the necessary shape. Despite its simplicity, this technology has its drawbacks.

Models for direct pressing, designed to work exclusively with simple materials, allow the production of simple products. Another disadvantage is the high cost of production, which makes it unprofitable to produce large batches.

For injection molding

The mold has 3 plates and a more complex device, it is multifunctional. Here, the matrix and gates locate independently in relation to each other. What products are made from injection molding? This allows you to design parts of different sizes. Due to the multifunctionality, many companies produce injection molded products, while the production requires relatively low costs.

The operation is only possible for professionals

The operation of injection molding models is only possible for professionals, as they are difficult to work with, are not easy to maintain, as well as expensive to repair.

According to the number of parts produced at a time, the molds are single and multi-place. The use of the latest molds allows the production of many parts at the same time, thereby increasing productivity and reducing the cost of production.

Mold material for casting: aluminum alloys, various steel grades, zinc alloys, and copper alloys. Aluminum plastic injection molds are common and are affordable and also have excellent performance.

What products are made from injection molding? machine for plastic panels

All owners of modern offices, shops and cafes, exhibition halls, and restaurants would like to make their premises clean, beautiful, and comfortable, but they do not want or do not have the financial opportunity to do so.

Today, it is absolutely not necessary to buy expensive finishing materials, since there is a large amount of finishing materials on the market that will look great and even solid. The best option, in this case, is plastic panels, which produce on a modern injection molding machine. It is worth noting that this finishing material will look great on your insulated loggia or balcony.

What products are made from injection molding? Plastic panels are indeed the most economical and simple finishing materials at the moment, which can be good to use in rooms of various types. Such a panel produces on an injection molding machine from solid polyvinyl chloride and from a softener.

The finishing material does not contain any harmful substances

The plastic panel can be good to use for interior decoration of kitchens, corridors, bathrooms, and loggias, as well as swimming pools, cafes, and restaurants.

Such panels are advantageous for finishing the interior of an office and various cultural and leisure facilities, sports and recreation complexes, and so on.

What products are made from injection molding?

This finishing material is quite popular in the domestic building materials market, it is much cheaper than siding and, moreover, natural wood. However, the panels are easy to produce not only in the classic white color, the manufacturer today has production technologies to imitate the texture and color of natural precious wood.

It must be said that when carrying out finishing work, cladding with plastic panels is easy to attribute to the most “clean” ways of finishing rooms. After its installation, no dust, no dirt, no waste, and no other construction debris will remain in the room. During installation, there are no problems with sizing, it perfectly cuts both along and across with a fine-toothed saw.

Proportional valves

In the process of molding plastics, exact proportions of the base material to the additional one are sometimes required. This makes it possible to achieve the requirements for molded products flexibly, mixing primary material with secondary material. To make this process simple and economical, a proportional valve for injection molding machines is good to use.

This equipment interacts with a vacuum loader and controls through a small controller. When using loaders of the SAL-U series, control occurs from the loader panel. It will make operation even more convenient.

Proportional valve operation

By means of the PV and PVN valve, a proportional loading of recyclables together with primary raw materials in certain proportions ensures. What products are made from injection molding? It is good to use with a vacuum loader. The proportional valve controls by its own control panel or vacuum loader.

When loading raw materials, while reaching a predetermined period of time, the supply of primary material is cut off by means of a pneumatic valve, after which the supply for recyclables opens.

After the specified time for supplying the secondary material, the pneumatic valve switches, and the supply of primary raw materials resumes. At the moment of stopping the loading of raw materials, the proportional dispenser stops.

The operation of the valve is based on pneumatic switching

The operation of the valve is based on pneumatic switching by external sources of compressed air. What products are made from injection molding? To operate a proportional valve, a pressure of 6-8 atmospheres is most often required. In operation, one of the loading channels always remains open and the other closed. Among the advantages of the device:

- Loading with one vacuum loader of two different materials, which have different fluidity and bulk density.

- There is no need to install a separate dispenser for crushed materials.

- Dosing carries out proportionally

What products are made from injection molding? Due to the stable operation of the magnetic valve, the precise operation of the pneumatic cylinder ensures strict proportions maintained between new and recycled material.