11 steps to make custom injection molds

System of plastic injection machine

Currently, the system of the custom injection mold will be divided into 2: the basic system and the injection molding support system.

The basic system includes:

- Clamping system

- Spray system

- Mold system

- Injection molding support system

- Control system

Injection molding support system includes:

- Machine body

- Power system

- Hydraulic system

- Cooling system

Classify

To classify, we need to be based on several factors: axis, size, structural principle.

Sort by axis

- Vertical press machine

- Horizontal press machine

Classification according to the operating principle of the mold:

- Molding Machine

- Plastic custom injection mold

- Plastic laminating machine

Classification by structure

- Water pressure machine

- Electric press machine

- High-frequency press machine

Sort by size

- Large presses (100 tons and 150 tons, 200 tons, etc.)

- Mini injection machine (Mini plastic injection molding machine and manual mini plastic injection molding machine)

The operator operates a custom injection mold maker

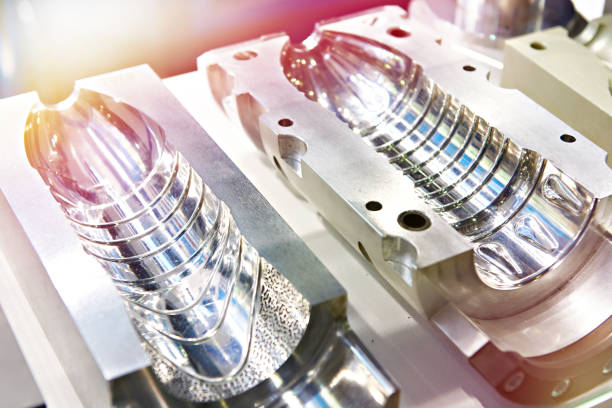

A plastic custom injection mold has the same operating principle as an injection pump. First, the plastic will be put into the storage hopper. Then, they will be liquefied by the heating rod at the appropriate temperature. Next, the entire liquid plastic will move forward thanks to the screw.

At the same time, the screw will move backward to create space for the plastic to flow into the front of the nozzle. Thanks to the thrust of the screw, the hot plastic will be molded. Finally, the cooling system cools the product before taking it out.

Uses of plastic injection machines

Plastic injection molding machines are used to create plastic products of various textures and shapes. They allow creating products with absolute precision compared to the design. In addition, you will make many products in a short time.

For simple details, in 1 minute, you will create about a few dozen products. Product quality is uniform, with no condition, distortion, breakage, or deviation from your design.

Custom injection mold knocks out conventional packaging and bottle manufacturing methods. When using, one thing is sure: the aesthetic value of the product will be guaranteed. Moreover, it also helps to save significant costs for businesses, promoting strong development.

Installation and repair instructions for plastic injection machines

Usually, the machine will be quite large. Therefore, you should prepare a large space to place the machine. In addition to the size and weight factor, the installation of the machine is quite simple. Most of the time, you will only need a stable power source and a large enough space to place the machine.

As for custom injection mold operation, you will find it challenging to do this job if you do not have too much experience. Usually, there will be one user manual for customers when buying the machine. However, you should have a team of technical staff with experience in this field to facilitate the operation and maintenance of the machine.

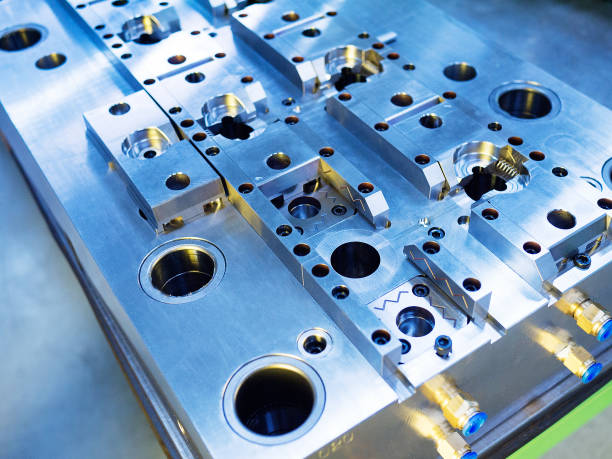

The mold assembly of custom injection mold

It is considered the most important step in the mold-making process because any error in the assembly process will directly affect the quality of the product. So how to make the process take place most effectively? The following article will introduce you to the following 11-step process.

What is the mold assembly process?

This is the process of joining together the parts in the mold after machining. Each set of molds will have a lot of parts that you will need to assemble. Therefore, the first requirement of every mold assembly worker is to be able to read mold blueprints. Because only then will they be able to conduct the correct assembly and shape the product.

Different types of custom injection molds

Currently, there are many different types of custom injection molds. They are classified according to the structure. It can be 2-layer mold, 3-layer mold, multi-layer mold. The 2-stage mold is the simplest type of mold. You can complete the assembly work in a short time. As for other types of molds that include a combination of many parts.

You will need experience in the field of mold making and the ability to read blueprints. Therefore, the time to finish this type of mold will take more than the 2-plate mold.

Mold assembly process requirements

For the mold assembly process or any manufactured product, technical requirements are always the premise for the manufacturer to rely on to contribute to creating the best quality molded products. Here are some key technical requirements in the process:

- Determine the exact number of parts in the mold set

- Define the correct process. At this stage, the technical department will print the design and send it to the assembly department. The job of the assembly department is to be able to accurately read and understand every detail.

- Master the parameters and procedures.

Steps in the mold assembly process

To complete assembling a complete set of molds, you will need to complete the following 11 steps:

- 1: You will need to determine the number of mold plates and import the mold plates into the model

- 2: Install guide bearings on the upper mold plates

- 3: Install the clamp plate with the upper mold plates

- 4: Install the spray stem silver to the upper clamping plate. At the same time, you need to install bolts to fix the two mold plates.

- 5: Install the mounting bolts to fix the positioning ring and install the positioning ring with the clamp plate

- 6: Install the guide pin on the bottom mold plate

- 7: You will need to install the ejector plate to the mold set

- 8: Install enough springs and two supports

- 9: Install nine return latches and fix plate

- 10: Proceed to install four bolts and a push plate to create a connection between the push plate and the retaining plate.

- 11: To make the movable part link, you need to install the top clamp plate and four bolts.

The process of disassembling the injection mold

To disassemble the mold, a special tool kit will be needed.

1: You will need to remove the main plates of the mold

2: Disassemble the focus injection system from the fixed plate

3: Remove the ejection system from the mold and proceed to disassemble the details of the ejection system