Why Outsourcing Your Work to Injection Mold Manufacturer Can Improve Your Business

Why Choose to Cooperate with an Injection Mold Manufacturer?

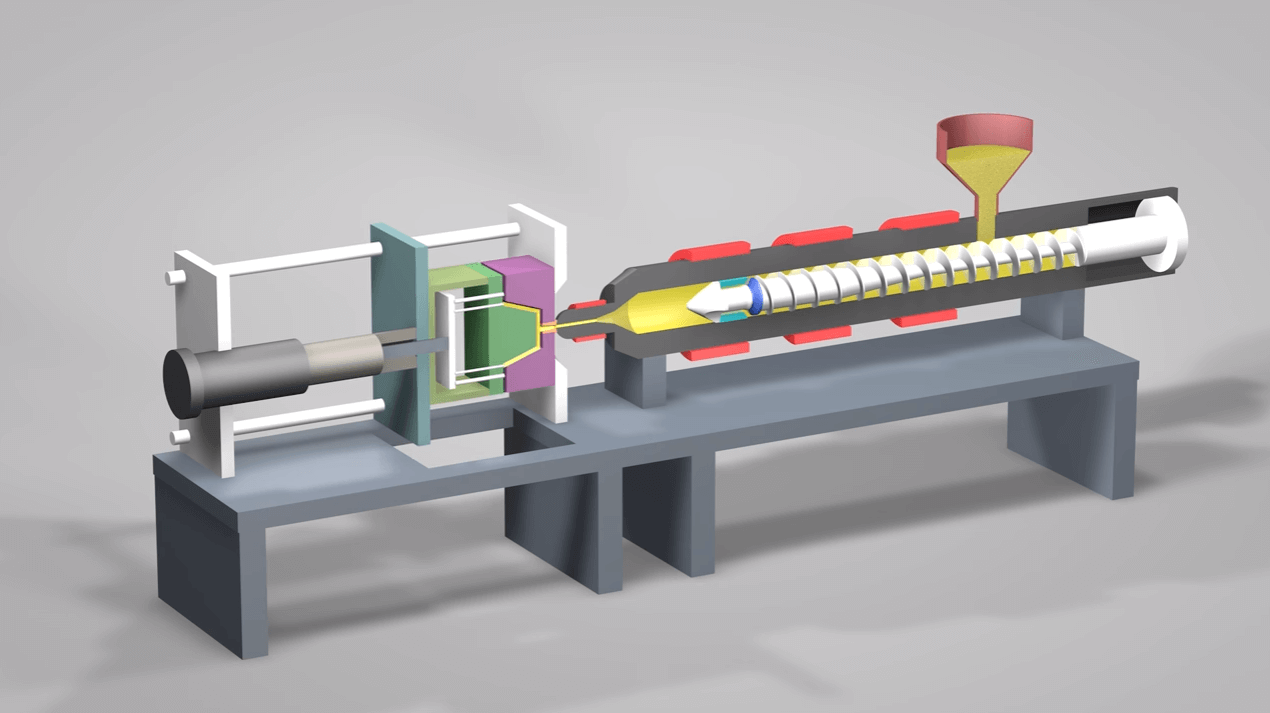

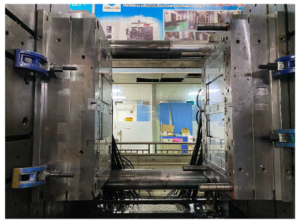

Manufacturing in-house components for your business customers can prove to be extremely challenging. It does not only require efficiency and quality but it can take up a lot of costs as well. This is where an injection mold manufacturer can come to your assistance.

When you outsource your work to them, they ensure that you get the highest quality at the lowest possible cost. Thus, it’s a win-win way for both you and your customers!

The Many Advantages of Hiring an Injection Mold Manufacturer for Your Business

Hiring an injection mold manufacturer for your business can benefit you in ways you never imagined. Want to know what those benefits are? Keep reading then.

1. Cost-Saving

One of the major advantages of outsourcing your work to a mold manufacturer is all the costs that you will save. While you may think that it is extremely easy to make such a small part, it is extremely difficult to understand the details.

Moreover, it is the details that matter as well. When there are detailed specifications related to a product, it requires expertise and sophisticated infrastructure to manufacture. What we don’t understand is that these technical machines take up a lot of financial investment for which the majority of us are not prepared.

This is exactly what outsourcing benefits you with. You will be able to get what you are looking for without incurring a lot of costs.

2. Improved Quality

At the point when the strategic policies of a company extend over numerous years, there is a reasonable distinction in quality contrasted with amateur organizations.

It additionally takes a group of experienced individuals prepared in various disciplines, like the plan, designing, tooling, administrators, hardware, and backing to guarantee that everything from the plan to the assembling to the quality testing is done to spec and as per quality prescribed procedures and principles. Having consistent cycles and excellent creation is also an advantage.

3. Streamlined Inventory

If you are manufacturing the products yourself, then you need to have an adequate supply of inventory with yourself. When you have adequate inventory for unforeseen demand for your business, it can prevent interruptions in the supply chain.

However, this increases the cost of warehousing as well. On the other hand, when you outsource your work to an injection mold manufacturer, they will be able to provide you the things you need whenever you need them.

As a result, you will not have to go through the process of getting a warehouse for your inventories. This will not only keep your customers happy but also make you be able to prevent supply chain interruptions as well.

4. Economies of Scale

Volume is basic to acknowledge economies of scale. The common companies regularly don’t have the staff or ability to take care of huge requests, nor do they have familiars plastic suppliers to drive costs down for huge material orders.

5. Experience

An injection mold manufacturer is much more experienced than the businesses producing the parts themselves. That’s because they deal in the manufacturing of the parts more than the businesses.

They understand that injection molding is more than producing the parts only, but also includes project management, quality assessment, resource planning, distribution, and packaging.

However, if you start in-house manufacturing, you will have to adhere to all the rigorous standards that you expect from an experienced manufacturer. This can be an extremely difficult standard to reach for some businesses.

6. Focus on Core Competencies

Hand over your plastic injection molding work to a professional injection mold manufacturer, then you can keep doing what made you fruitful in any case without extra staff, preparation, and framework, as well as keep on zeroing in on your core ability.

7. Avoid Risk

We all understand how daunting can high initial investment to start your own injection molding setup be. There is a lot of things to consider such as sales, demand, order volume, economies, and other factors that can affect the return on investment of your business.

When all these things are combined, this adds a considerable level of risk to your business. However, when you outsource your work to an injection mold manufacturer, you can avoid all these risks as the risks are transferred to the manufacturer.

8. Faster Start-Up

When you outsource your work to an injection mold manufacturer, it can save you the cost and time that you require to establish an injection molding shop. Thus, why establish a setup for molding when there are already so many manufacturers out there?

9. Less Labor

The work benefits are likewise significant. With numerous organizations scaling down staff inside their form producing tasks in recent years, it is a higher priority than at any other time to utilize professional mold makers on the better subtleties of the shape—chipping away at the mind-boggling molding point of interest, complete the process of granulating sensitive swipes by shut-offs and straightening outfits are on the whole positions that can’t be normalized.

These subtleties take the skill just accessible from the hands of qualified mold makers with a serious level of ability. This is the place where organizations bring in their cash and for what the client is at last paying.

A mold maker doesn’t need to stress over assigning labor to make these parts. Utilizing whatever number norm off-the-rack things as would be prudent can diminish lead times and increment benefits by expanding your accessible shop hours.

10. Less Scrap

The scrap is extremely insignificant when you outsource your custom mold to a mold manufacturer. Thus, the expense of causing scrap becomes lower too. Hence, most companies are presently changing to this innovation.

Final Words

There is no denying the fact that there are many advantages associated with outsourcing your work to an injection mold manufacturer.

You can not only cut the cost but also start your business in an extremely short period. That’s why more and more business owners are now adopting this method. Need more information? Welcome to contact us now!