Injection Molding Machine: Leading Choice of 2022

Choose the Right Injection Molding Machine

Are you looking for a quality Injection molding machine but still wondering how to choose the right and secure one? Rest assured! It is easy for you to choose the most suitable plastic injection molding with the following introduced criteria. Let’s find out together now!

What to Pay Attention When Choosing a Plastic Injection Molding?

Referring to plastic injection molding, people will immediately think of outstanding advantages such as high productivity when it is possible to crush many different materials, helping businesses save a lot of labor costs.

Moreover, the machine is also highly durable, “friendly” to the user. Therefore, it is understandable those plastic injection moldings are more and more widely common.

However, when applying an injection molding machine to the production process, you should also pay attention to choosing the type of machine in accordance with the production plan, machine capacity as well as product results. And to choose the right type of plastic injection molding, you need to consider the following seven criteria:

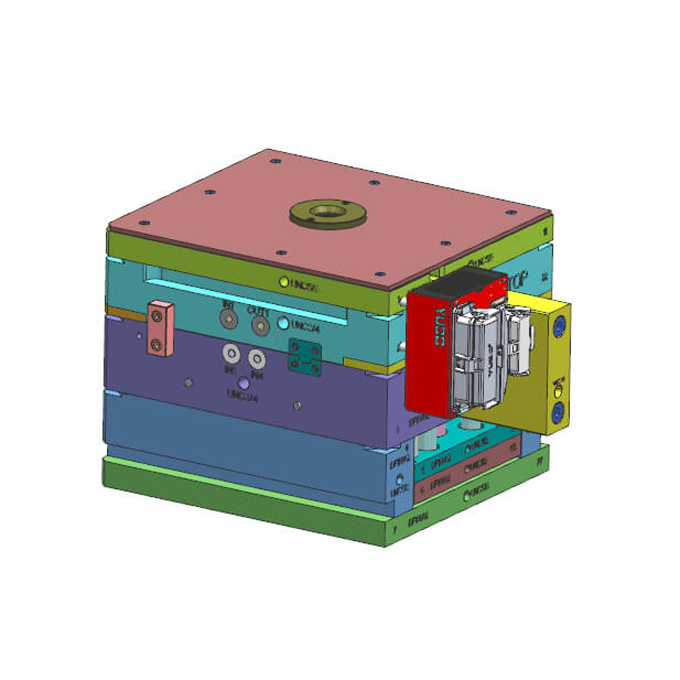

Two-Layer Texture Plastic Injection Molding

The first criterion you need to pay attention to is choosing a plastic injection molding machine with a two-layer structure. But why should you choose a molding machine with a two-layer structure?

The chopper has two-layer. Furthermore, it will make the machine more solid, reducing vibrations when operating. Thanks to that, the machine is also capable of highly impressive noise reduction.

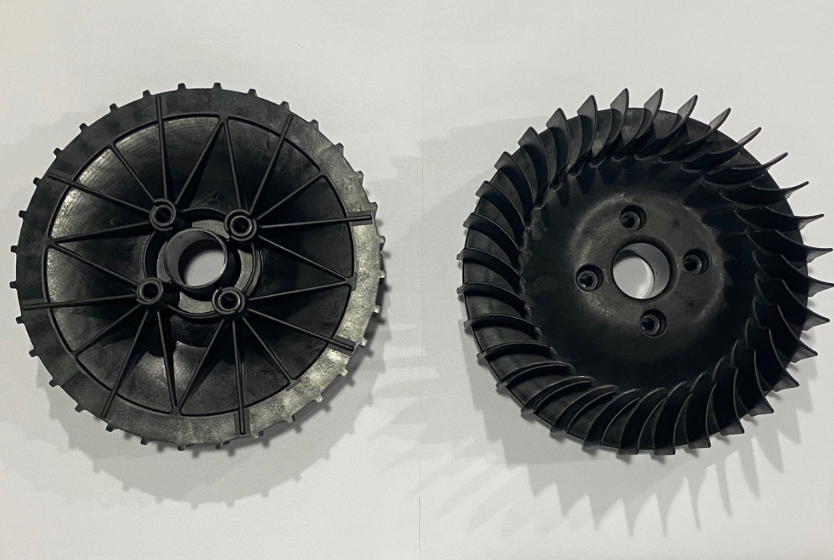

Even and Balanced Flywheel

The next criterion is to choose an injection molding machine equipped with wheels that are both sides and balanced. This will increase the hashing force, make the chopper more efficient, and save energy when operating. At the same time, the chopper has a balanced flywheel that also contributes to effective noise reduction and anti-vibration.

A Machine with Sensor Function

The third factor to keep in mind when buying plastic injection molding is to choose a machine. It should come with a sensor function. This is one of the most important criteria to choose a plastic injection molding that you should not ignore. Most plastic injection moldings on the market today are not equipped with this feature.

Therefore, it will be very dangerous if we are careless during operation. Therefore, to ensure safety, choosing an injection molding machine equipped with a sensor function should be a top priority.

Chopping Reel and Transparent Screen

Choose a hash machine with an appropriate hashing wheel with a screen to prevent the hash from flying out. This not only helps ensure worker safety but also makes it easier to see inside.

Good Chopping Knife of Machine

The fifth criterion is to choose a chopper with a really good set of knives. This will be a decisive part, affecting mainly the hashing capacity of the machine.

And we can say that this is the most investment-worthy part of the injection molding machine. When the chopper comes from high-quality materials, it will have a long service life, minimize wear and bring impressive efficiency in productivity and economic value.

Injection Molding Machine with a Cooling Unit

Choose a scrap plastic injection molding with a cooler. This part plays an effective and quick role in cooling the shaft and chopper. This makes the machine work more stable, durable, and efficient. At the same time, the cooling element also helps to limit the wear process. As a result, the life of the machine is also increased.

A Chopper That Can Be Easy to Disassemble

The last and not least criterion is to choose a chopper that can be easily disassembled. In the process of using it, we need to regularly maintain the machine. And with an easily removable chopper, it saves maintenance time and improves productivity significantly.

The use of mechanical equipment and errors is not uncommon, no one wants that, but you need to equip yourself with the minimum knowledge about errors to be able to work with peace of mind or quickly handle errors. Basically, without interrupting production, below are the problems with the plastic injection molding machine and how to fix them.

Malfunctions are alerted by error lights Consists of:

- Thermal motor (Motor temperature)

- Engine (Main Drive)

- Vacuum pump (Vacuum pump)

- Cooling oil pump

- The main motor load alarm (% torque) drifts to 95% (The main motor alarm 95%)

- The main motor stops at 110% load (The main motor shut down 110%)

- Metering Unit

- Screw heating/cooling (Screw heating/cooling)

- Melt pressure warning of plastic flow

- General introduction of plastic mixer

A plastic mixer is generally a kind of specialized hot and cold mixer for the plastic industry. The injection molding machine is mainly common to mix PVC raw materials in the form of powder and additives, thereby producing high-quality plastic products.

Plastic mixers are divided into two main types: vertical mixers and horizontal mixers. These two types of machines have very different characteristics and use. Specific in:

Vertical Plastic Mixer injection molding

Externally, the stand mixer has a circular body with a wide flared top like a funnel. This type of machine is common to mix plastic granules. The pieces of plastic are chopped, crushed, with low moisture.

The injection molding machine works by spewing ingredients up to mix and stir well. The advantage of this type of mixer is that it has high efficiency, low cost, and is easy to put raw materials in.

Vertical Plastic Mixer Horizontal Plastic Mixer

Horizontal plastic mixers are more compact in design and size than vertical mixers. This is a low-speed plastic mixer, common for mixing pigments with resins, drying, and dyeing plastic raw materials.

The horizontal plastic mixer can mix different types of plastic, plastic beads of different colors to create colored plastic products or plastic mixtures according to production needs. Thanks to its ability to mix evenly, the machine is very popularly common for quality finished products.

The price of the horizontal plastic mixer is quite high because the motor needs a very large type to be able to mix the materials. It is also easier to feed ingredients into the horizontal plastic mixer than in the vertical mixer.

Specifications of Injection Molding Machine

The mixing tank comes in the shape of a U, made of stainless steel material, durable, easy to clean, and hygienic. The mixing blade comes of high-strength stainless steel has a two-way S-shaped spiral design, circular motion on a fixed axis, allowing rotating, shock, and mixing ingredients quickly and evenly.

The base part has a very solid structure, helping to keep the machine firmly on the ground when operating. The reducer motor supports slow rpm, which increases the quality of the finished product.

The protective door is specially designed easy to maintain.