A Detailed Comparison of Injection Molding and 3D Printing for an Injection Mold Manufacturer

Plastic injection molding and 3D printing both are highly addictive processes that create incredibly complex parts with the help of near-identical runs. While the injection mold manufacturer can choose a broad collection of thermoplastic and plastic materials from both of these processes, there are a few special applications where they prefer 3D printing or plastic injection molding.

So, if you also want to know which method is best for which application, we have prepared a comprehensive guide for your convenience. It will help you understand all the differences between the two methods. In the end, you’ll decide by yourself which method to go for.

So, let’s get started!

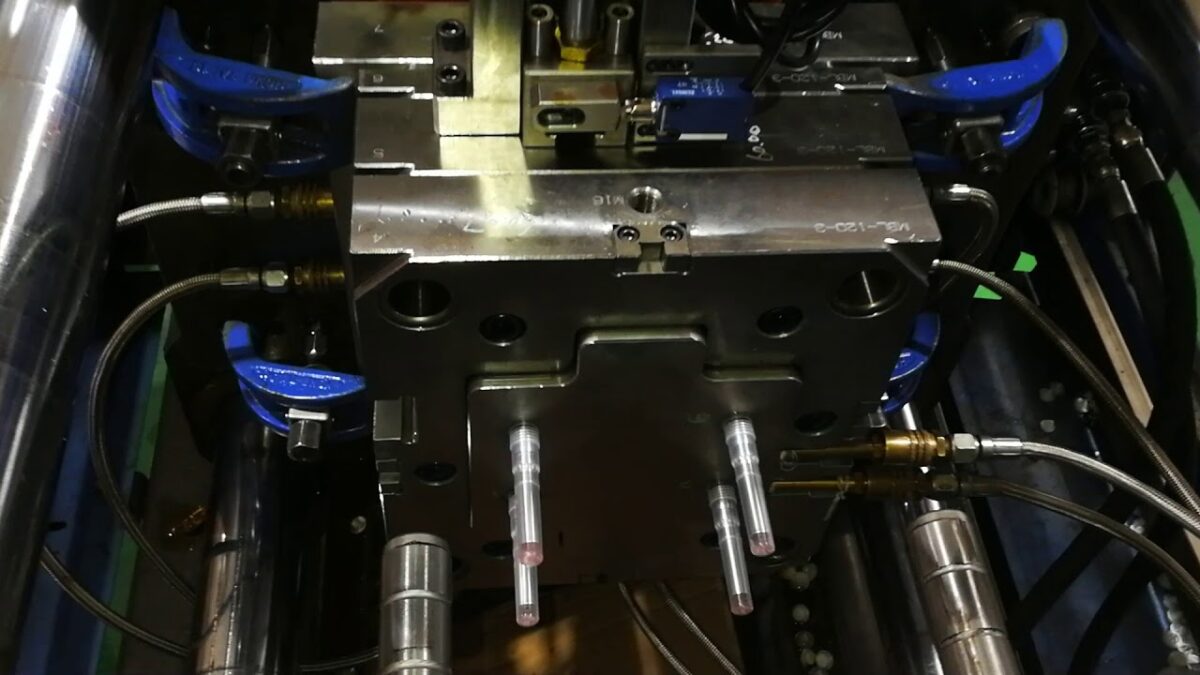

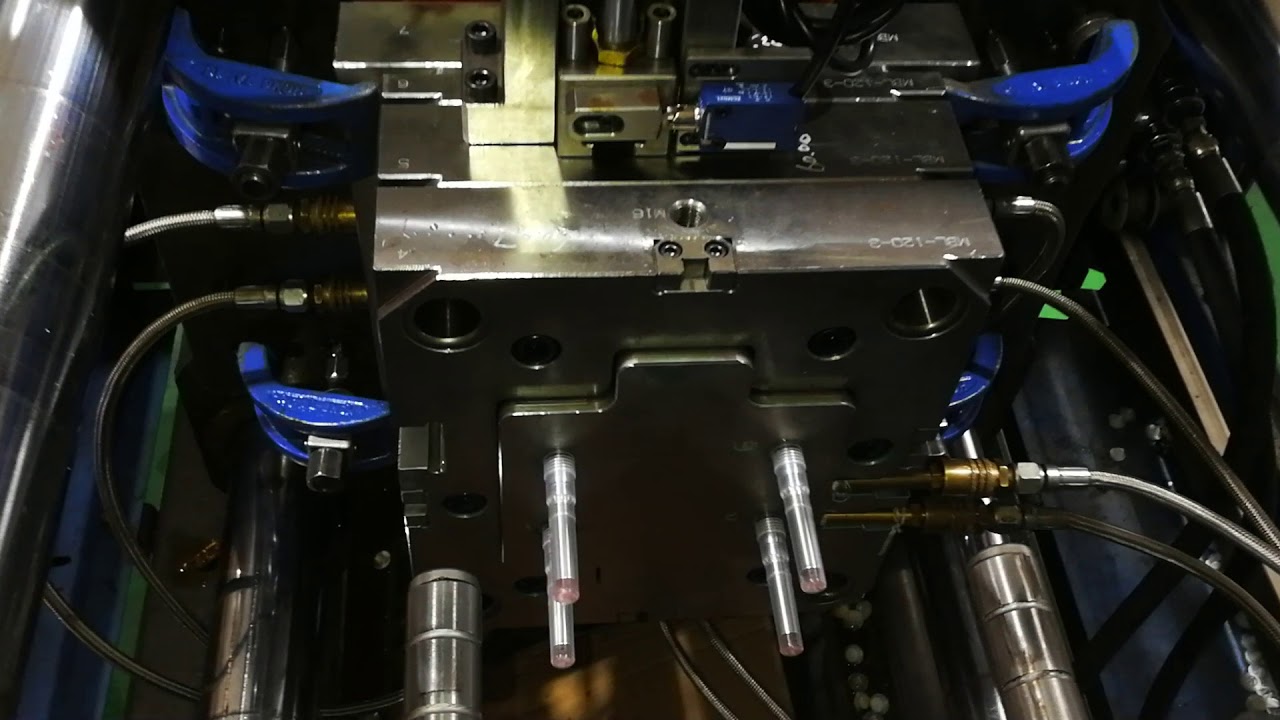

Introduction to Plastic Injection Molding

Plastic injection molding is the method that the injection mold manufacturer joins two plastic materials into one shape. This can incorporate the materials that have various properties, two unique materials of various tones, or two hard and delicate blend materials.

The compound holding of the 2 sections happens because they join into one another or because the fundamental fragment is grown so the resulting portion securities definitely. Sometimes, it is useful that the two materials don’t hold quickly to each other. In this manner, parts can be “molded” in the structure.

Advantages of Plastic Injection Molding

There are many different advantages of plastic injection molding that you should know. Let’s take a look at some of them below.

1. Low Unit Cost

One of the primary advantages of this is method is the lower unit cost that it offers to the manufacturers. That’s because replicating the prototype is extremely simple after building the mold. All you need to do is injecting the molten build material at high pressure into the mold. After this, you can cast the product and finish it as you require. Since this method uses raw resources efficiently as compared to the other processes, it doesn’t produce a large amount of wasted material. This is what makes it a relatively cost-effective method as compared to the other methods out there.

2. Product Quality

Plastic Injection molding has good precision. Each millimeter of the shape is completely filled to forestall air pockets, division, or other plan blemishes. An item made with injection molding will be finished without creases or gathering, so the surfaces will be smooth and have utilitarian respectability. This produces all the more outwardly engaging and dependable parts contrasted with those that are made with 3D printing.

3. Speed and Accuracy

While the speed and accuracy of this method depend upon the type of plastic that you use, it is a relatively faster process as compared to 3D printing. You can set the products in just a matter of seconds. Also, since a lot of plastics do not require finishing, this further cuts down the production time.

Disadvantages of Plastic Injection Molding

There are some disadvantages of plastic injection molding as well that an injection mould manufacturer should be aware of. Want to know some of them? Keep reading then.

1. Upfront Investment in the Mold

A major disadvantage of this method is that it requires a significant portion of cost towards the creation of mold. So, if the plastic product has a low demand or a shorter life, it can be more expensive than using a 3D printer.

2. Modification Limits

You cannot modify the mold once it is created without recasting it or editing its product design. So, if you are in the testing phase, we’d suggest that you use a different method until you finalize the design.

What Is 3D Printing?

3D printing is a process that manufactures plastic projects in layers. You can even watch the entire process during the manufacturing of the product. 3D printing utilizes computer-aided design records to fabricate three-dimensional parts layer by layer. The 3D printer utilizes a fiber to make vertical layers that stack on top of one another; it makes each item in turn. It can help you a lot when you are testing a new design.

Advantages of 3D Printing

3D printing offers many different advantages to the injection mould manufacturer. Some of them are mentioned below for you to check out.

1. Lower Initial Cost

One of the greatest attractions of 3D printing is that it has a lower initial cost as compared to plastic injection molding. That’s because this method does not use specialized dyes. Once the design file is complete, you can take the assistance of the printer to create either one or hundreds of the products at a lower cost per unit.

2. Flexibility

Flexibility is another prominent advantage of this method that a manufacturer gets to enjoy. Since it uses a computer file and not a mold, the printers can easily accommodate any changes that you want in the product design. This is what makes it suitable for prototyping when you are testing different stages and designs.

3. Supports Multiple Complicated Designs

Since this process works by adding layers on top of each other, you can create multiple complex designs and intricate infrastructure of the object.

Disadvantages of 3D Printing

Just like every coin has two sides, there are some disadvantages of 3D printing as well. Let’s take a look at some of them below.

1. Technical Issues

Since 3D printing is still in a developing phase, the software and hardware might occasionally malfunction. This can lead to low structural integrity and errors. So, you must identify them in the process of quality assurance.

2. Slow Speed

As we know that 3D printing works by building layer by layer, it slows down the entire process of manufacturing. So, you will have to be extremely patient while working with this technology. This is what makes it suitable for orders of only a few hundred units.

Final Words on Injection Mould Manufacturer Preferences

As an injection mold manufacturer, you must know all the ins and outs of plastic injection molding and 3D printing. This is important so that you can decide which method to pick under different circumstances. We hope the above guide helped you in differentiating between the two methods. However, if you still have any questions, please feel free to contact us!