Inspection and Delivery

-

-

-

01

To do Sample Assembly

For T0 samples, our team would check if the part is made completely. If yes, we will finish the CMM report after 24 hours molded. Mostly our customers would come to Tip-Top to attend the mold trials. They would use the T0 samples to do their assembly. If there is any interference or defaults on the assembly, the customer’s engineer would change the part design in accordance and will send us new data for engineering change. For too big deformation, both sides would work out some ways to improve till the assembly works perfectly. If our customers could not attend the mold trial, we will send the samples together with the molding process to our customers for their verification.

-

-

-

-

02

Delivery Approval

We would supply a fully dimensional CMM report for approval based on T0, T1, and/or T2 samples optimized. After the customers approve the CMM report, it means the molds are approved for shipping meanwhile there is not any interference with the assembly.

-

-

-

-

03

To Pack the Molds and Get Ready for Shipping

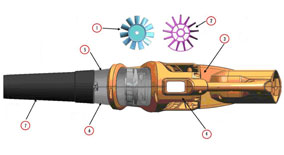

Per the customer’s pre-ship checklist, we would do the final checking and cleaning, such as if the mold actions are normal and smooth for cooling lines, ejector pins, slides, lifters, hydraulic cylinders, and air cylinders. We would check if all the engravings for each component are clear and done. We would also check if the spare parts are well prepared for shipping. Tip-Top Molds would supply a mold book including 2D and/or 3D mold design disc, steel certificate, heat treat certificate, molding parameters, and the fully dimensional CMM report. All the final files could be digital or written style per our customer’s request. For different shipping ways, we will do different anti-rust protection for the molds. When everything is prepared well, we would package the mold up for shipping.

-