The Grip Part of Lawn Blower-Overmold- Injection Mold

This is an injection molded part from an Overmold, which is the Grip Part of a Lawn Blower. Its plastic substrate is made from ABS, red and the plastic overmolding part is made from TPE, black.

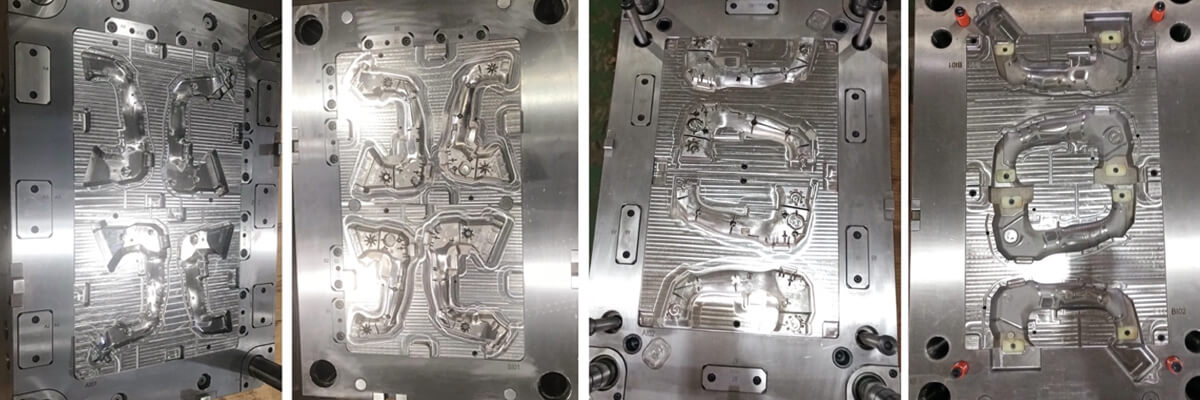

This part is produced by two molds, including a 4+4 cavity plastic injection mold and overmold with the hot runner, of which cavity and core blocks are made of H-13 steel. Their mold type is High Volume Production Tool. Besides, the mold surface finish for this part is SPI-A2 standard and the texture includes MT1055-3, MT-30008, and MT-1102. Furthermore, the sizes of these two molds are 850*600*570mm and 750*500*480mm, and their net weights are 1955kg and 1225kg. The mold’s service life would be 1,000,000 shots.

Both the plastic injection mold and the overmold are made by Tip-Top molds in Shenzhen, China. The molded part on the picture you’ve seen is also the sample we produced for customer’s verification. After the mold trial every time, we delivered the samples to our American customers by UPS, FedEx, or DHL. Molds are too heavy to take the express delivery so they were delivered by the logistics company after being packaged in wooden boxes. We would help to handle it, but of course, customers could arrange their own freight forwarder too.

Lawn Blower Injection Mold Manufacturer Professional Plastic injection molding service

Specification

|

Part Material |

ABS-Liberty Red + TPE–Black |

|

Part Application |

Grip Part for Lawn Blower |

|

Selling Units |

2 Molds: Plastic Injection Mold + Overmold |

|

Mold Type |

High Volume Production Tool |

|

Mold Details |

4+4 –Cavity Overmold with Hot Runner |

|

Mold Finish |

a.MT 1055-3 b.MT-30008 c.SPI-A2 d.MT-11020 |

|

Mold Steel |

Cavity and Core Blocks: H-13 |

|

Mold Size |

850*600*570mm, 750*500*480mm |

|

Mold Weight |

1955kg, 1225 kg |

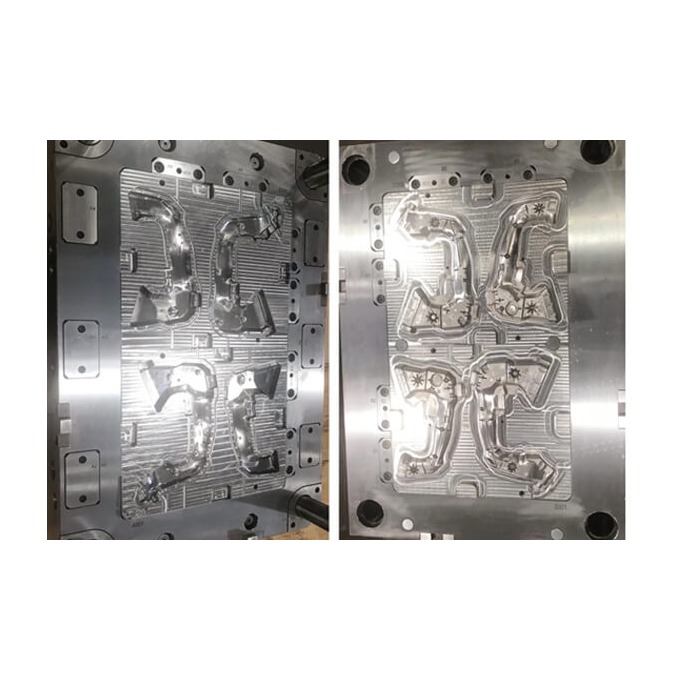

Mold Photos

|

Place of Origin |

Shenzhen, China |

|

Package Type |

Wooden Box |

|

Inner Box Size |

950*700*680 mm, 850*600*550 mm |

|

Outer Box Size |

1000*750*790 mm, 900*650*690 mm |

|

Gross Weight |

2015kg, 1275 kg |