Injection molding helps in making toys to car body parts, phone cases, water bottles, and containers. Lastly, many of the plastic products we use in our daily lives are molded under pressure. This is a quick process of creating identical plastic parts.

Ability to perform different shapes and sizes, achieved by using injection molding. The boundaries of design are consistently expanding, which allows the use of significant alternatives to traditional materials due to the large variety of products and their lightweight.

What is the function of an automatic injection molding machine?

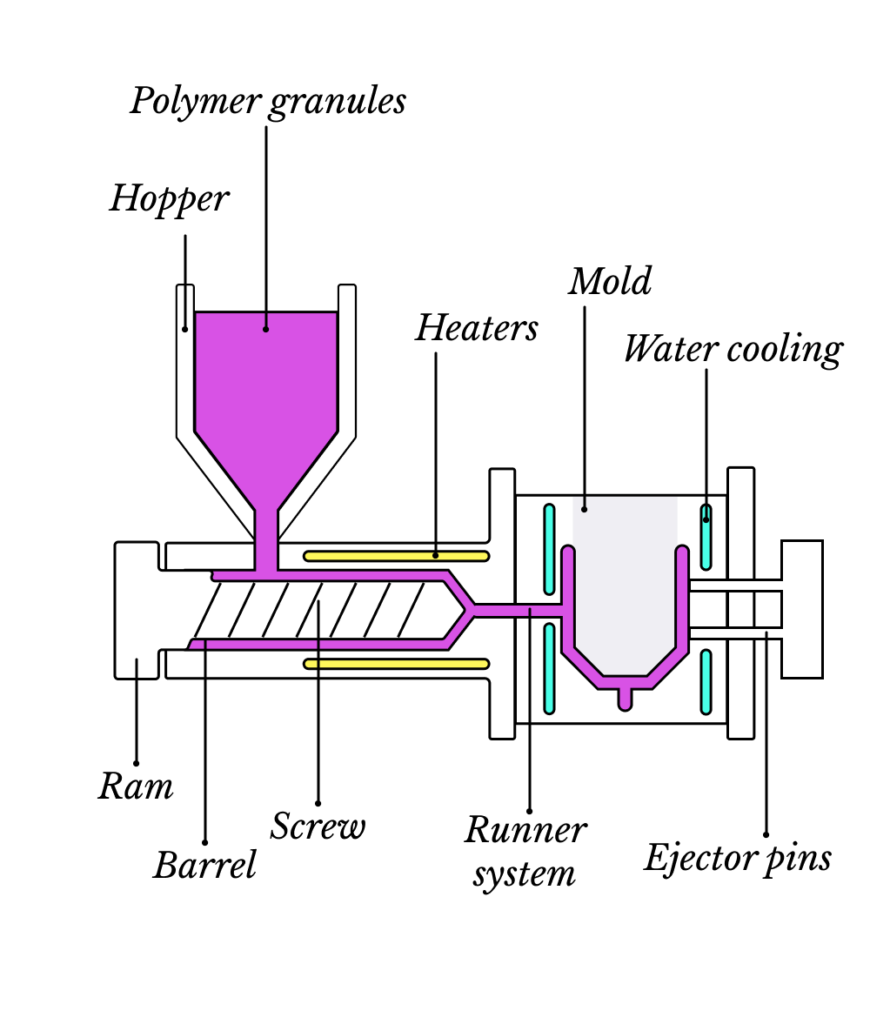

The automatic injection molding machine produces polymeric products by injection molding and consists of three main components – the loading bunker, the screw, and the cylinder.

The plastic that is placed in the hopper usually has a powder or granular shape. Then the material melts due to the frictional action of the piston auger and the operation of the ring or semi-ring electric heaters.

Molten plastic vs Injection molding

Molten plastic may seem like a fairly simple process, but injection molding is a very complex type of production. While for injection molding in the cavity of the mold, the material is cooled and solidifies to the configuration of the cavity. When the part hardens, the movable half on which the form is established opens.

The dimensions of the injection molding machine can vary from 5 tons of clamping force to more than 6000. The larger the tonnage, the larger the molding machine.

Classification of injection molding

Injection molding machines are classified based on tonnage, or, more precisely, clamping force or pressure. The automatic molding machine is easy to equip with a hot runner system.

The most complex and high-quality products for injection molding are easy to make using hot-runner systems. Let’s talk about the nuances of working with them. The temperature at which the processing of polymers in the gutters affects the quality of the final product.

Thermal component role in injection molding

Also, the thermal component in the molds during molding will affect the temperature of the molten polymer raw material in the cavity of the mold. This subsequently at the time of curing and the appearance of the finished product.

If the temperature regime of injection molding is violated, a plug of hardened material may form in the intake manifold. Which will stop production. It is important to consider the thermal regime. Heat distribution on the pouring channels, the method of temperature control and regulation when choosing the design of GCS parts, and the temperature control system.

Thermoplastics role in injection molding

Thermoplastics are thermally unstable materials, so increasing the thermal values during production, is necessary to reduce the residence time of the melt in such conditions. But here there can be a second problem in the form of a decrease in stability of process and quality of finished goods.

The uneven effect of the temperature of injection molding is on the molten polymer increases the risk of destruction of the material. Especially often such problem arises in the conditions of a long cast cycle which is characteristic of the production of details with thick walls.

Drawbacks of injection molding

Some of the problems of injection molding and temperature control of pouring channels of TEN 24 is the subject matter ahead. Overheating of the molten polymer, which occurs due to too high a temperature effect.

Or increased residence time in the heating zones leads to changes in the characteristics of the polymer product. Overheating may be accompanied by an unpleasant odor, and the product will show dark spots, strokes. For injection molding, you can also see the destruction and inconsistency with the stated size.

Drawbacks for injection holding

Considerable problems can arise when changing the color of polymer raw materials. On the walls of the channels of the spout can form fixed layers of polymer of another color. The polymer is easy to deposit on some types of nozzles.

What affects the temperature of the polymer in the gutters?

The most important source of heat in the processing of polymers is the dissipation of temperature in the melt. This heat arises from two mechanisms: flow shifts and compression of the material. The rate at which heat q is released in the molten polymer mass in shear flow per unit volume is:

1-q = η ŷ²

For injection molding, first, η effective viscosity (depending on the shear rate, temperature, and pressure)

2- ŷ – shear rate.

The temperature rise ∆T of the polymer mass under adiabatic compression of indeterminate volume with a simultaneous increase in pressure by the value of P is easy to calculate by the following formula:

3-∆ T = ∆ P / (Cp)

P is the average density of the molten polymer; Cp is the average specific heat of the molten polymer under constant pressure. Dissipation in the polymer comes by shear flow is a major contribution to the overall heat balance during casting.

The greatest amount of heat for injection molding is released during plasticization and injection because the shear rate is very high. The dissipation that comes by compression will differ in different areas of the ACS. Due to changes in the pressure of the polymer mass during the casting cycle, dissipation will change over time.

How does injection molding work?

Through the channels of the spout and in the cavity of the mold, the melt at the loading stage proceeds due to the increase in pressure drops throughout the system. The dissipation that comes by compression at these stages has almost no effect on the temperature of the polymer.

In injection molding because of the pressure in the flow areas close to atmospheric values. Moving away from the flow front, the effect of dissipation increases. The temperature of the polymer in the ACS affects by the temperatures of the material.

An overview of heat balance

The total heat balance includes the heat produced by the heating elements placed in the GCS and the collector. Electric heaters are common for hot-channel casting in modern equipment. Heat losses in the forms of hot-channel casting can occur for various reasons.

- Firstly, thermal conductivity

- Secondly, convection

- Thirdly, heat radiation

Cooling of the molten mass can occur due to its expansion due to reduced pressure.