INJECTION MOLDING – HOW DOES THAT WORK AGAIN?

How does injection molding work? Of course, we’ve already covered the injection molding process on our website, but when we talk to visitors, we keep finding that there’s interest in the basics of the injection molding machine. Therefore, we would like to summarize some of the basic terms and the rough process of plastic injection molding.

THE INJECTION MOLDING MACHINE

According to the definition, an injection molding machine is a system for the discontinuous production of molded parts made of different types of plastic. These are usually delivered in granular form. The most commonly common plastics come from the group of thermoplastics.

How does injection molding work? Thermoplastics become liquid when heated and solidify in the assumed form when cool. This process is repeatable. Thermosetting plastics and elastomers are common less often. These two types of plastic crosslink so much during the solidification process that they can no longer soften afterward.

There are major differences in injection molding in terms of pressure and temperature distribution. For the description of the injection molding machine, we shall use one of the simple elastomers.

Thermoplastic injection molding

How does injection molding work? In principle, plastics will be heated to such an extent that they liquefy. The thermoplastics are then filled into a die called a tool using a screw, pressed together, and cool. After that, the desired shape solidifies and can be removed.

The whole process closely time so that granulate for the next component is already being filled into the screw while the cooling process is still running. In this way, thousands of components can be produced in a relatively short period. The injection molding machine consists of two assemblies, namely the plasticizing unit and the closing unit.

THE INJECTION UNIT OR PLASTICIZING UNIT

How does injection molding work? In the injection unit or plasticizing unit, the plastics are usually fed in granulate form through a hopper and prepared for injection molding. To do this, they must be heated, liquefied, and homogenized.

The machine’s injection unit, which shapes like a cylinder heats from the outside by heating coils or bands. A screw is rotating inside sizes to fit snugly within the barrel.

While the granules are transported forwards by the screw towards the nozzle, they are also heated, grounded, and mixed or distribute by friction.

The plastic, which is evenly liquefied in this way, is prevented from flowing back when it reaches the nozzle by a non-return valve. This builds up a certain pressure with which the plastic compresses.

How does injection molding work? Then the plastic is pressed through the nozzle with another forward movement. At the same time, the nozzle also takes care of the dosing by closing precisely calculate and thus interrupting the injection.

The auger then retracts to process the next batch of granules. In this injection phase, the material is pressed into the clamping unit under very high pressure of up to 2000 bar, which can be up to 2000 bar. The filling speed must of course be calculated extremely precisely so that no cavities or cracks form in the workpiece.

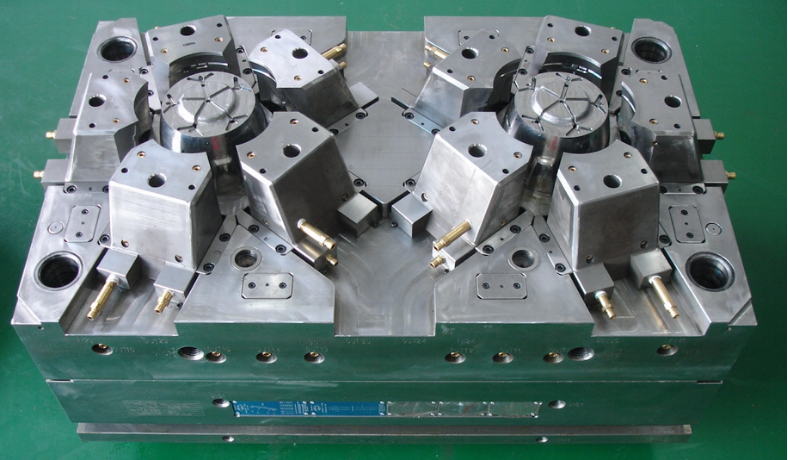

THE LOCKING UNIT

How does injection molding work? The clamping unit contains, among other things, the shaping tool. This tool is mounted on two vertical plates. The tool forms the more or less complex cavity, i.e. the matrix, in which the new shape of the plastic creates. A stationary plate with one-half of the tool attached to the plasticizing unit with the screw.

The nozzle inserts through a hole in the middle of this so-call clamping plate. The second moving plate is usually brought up to the first plate on horizontal bars before the plastic injects. It carries the second half of the tool.

A third plate provides the pressure on the two clamping plates and connects to the moving plate by a hydraulic cylinder, electric motor, or mechanical toggle lever.

How does injection molding work?

The two clamping plates initially heat in such a way that it corresponds to the liquid mass. Additional pressure generates during injection, which gives the liquid plastic its shape in the tool. A certain holding pressure requires compensating for the volume loss of the plastic that occurs as a result of cooling or hardening.

Therefore, after the actual filling, some more liquid plastic still has to push in until the workpiece is perfectly shaped. After a short cooling phase, the moving plate moves away from the nozzle side to the ejector side.

How does injection moulding work? The injection mold part contained in it is then ejected. Which occurs as a result of cooling or hardening. Therefore, after the actual filling, some more liquid plastic still has to push in until the workpiece is perfectly shaped. After a short cooling phase, the moving plate moves away from the nozzle side to the ejector side.

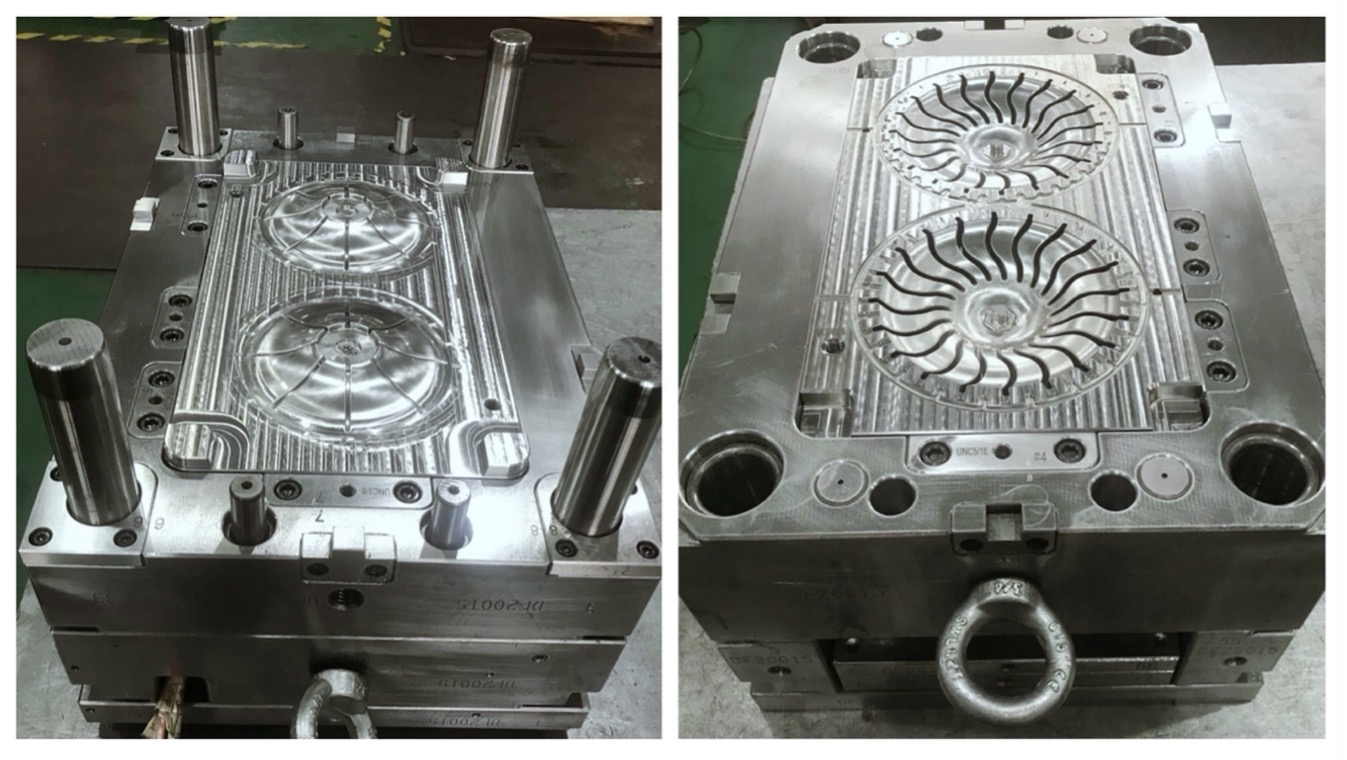

The tool must be made of the best metal

How does injection molding work? As already mentioned, the tool represents the mold that gives the later injection-molded part its shape. Depending on the order, this can be a relatively simple Lego brick or a highly complex functional part, for example, a machine.

In any case, the tool must be made of the best metal in order to withstand the processes over the long term.

Hardened steel is usually common for this. Some manufacturers only use aluminum tools in exceptional cases and, for example, for small series. The tool manufactures with the greatest precision, nowadays mostly using 3D CAD specifications.

How does injection molding work?

It is the manufacture of this tooling that accounts for the lion’s share of the cost of injection molding. In plastic injection molding, molten plastic injects into the forming cavity (cavity) of a tool, compressed under pressure, cross-linked, or allows cooling, and then ejected as a mold part.

Conclusion

How does injection molding work? Injection molding is the most common process for the highly automatic production of plastic workpieces by processing powder or granules. Workpieces with complex shapes can produce in almost any size. The high level of accuracy and short cycle times predestine the process for economical series production.