Injection molding is the best way to get custom molding products. Larger machines can cast car parts under pressure.

Smaller machines can produce very precise plastic parts for surgical use. The injection molding process increases the flexibility of the process for designers and engineers.

Significance of custom molding

The low cost of the manufactured part, along with polymers and processing options. All this has contributed to the popularization of injection molding in the modern manufacturing sector. Individual injection custom molding with small tolerances is an ideal solution for many industries. That seek to produce many parts of high quality and precision.

Food Industry as an application of custom molding

To ensure optimal human health safety, food and beverage industry standards require that the manufacture of parts meet many specifications and clear standards: they do not contain BPA and other toxic ingredients and meet.

For example, the standards of the FDA (Office of Health Supervision). quality of food and medicine, USA). Various food materials are common for injection molding of plastics in the food industry: safe for both the end-user and for professionals who work directly with the equipment.

Material required for custom molding

At the same time, the materials common for custom molding can provoke faster wear of the mold, contamination of equipment, blocking of fasteners, and, consequently, reducing production efficiency. That is why professionals advise using special oils and tools to protect and preserve equipment, molds, and tools.

The variety of plastic parts that we encounter every day – is very large, and every day they become more and more. Plastic products are common by more than 90% of the world’s population, in this regard, the processing of plastics is developing very rapidly, there are new technologies for plastic casting.

List of steps to find custom molding

A large niche in this area is occupied by injection molding of plastics with the help of a tool called – a mold. There are several steps to getting a finished plastic product.

- Detail design

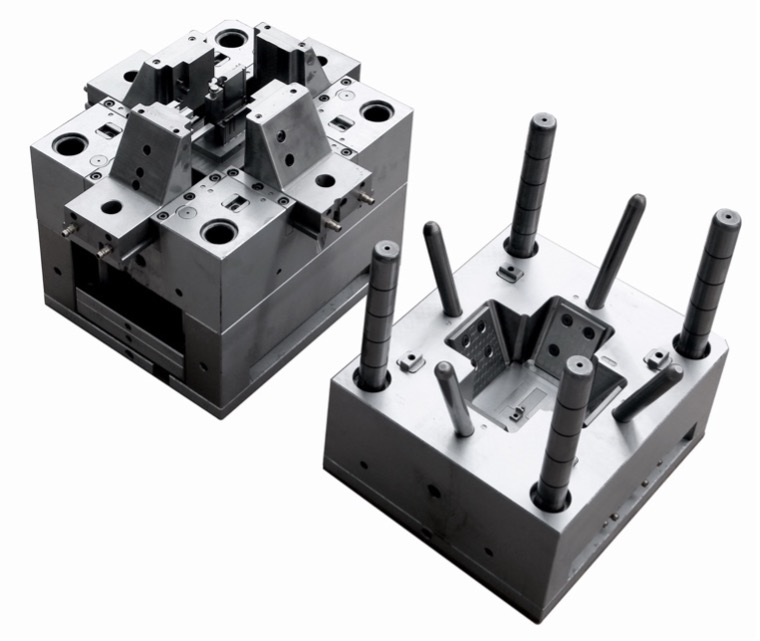

- Construction of the mold according to the drawings

- Also, making a mold.

- Checking the efficiency of the forming equipment

- Product casting

- Product design

All stages of mold part development are done using software (CAD). The use of CAD for custom molding reduces the time spent on development, reduces the percentage of design errors in the design of the mold. Furthermore, the designer of equipment (molds) makes a mathematical design of the 3-d model on the information given to it from the customer.

Factors for creating a 3D model

To create a 3-d model, such important factors as:

- Product Individuality

- Material Characteristics

- Product Part Optimization

The result will be a model and a drawing of the product. At this stage, an important role will be played by the correct creation of a 3-d model of the part. Also, custom molding can be common to evaluate the product and its forming equipment.

Design of custom molding

When the development of the part is completed, the design engineer begins cooking to design the mold. The choice of components for molds is of great importance. Moreover, the stability of the form, quality of a forming surface of the form, ability to give of processing of working parts, and quality of the future plastic product depends on the material.

Steels with a hardness of 30… 32 HRC are important for the correct operation of the mold. In addition, they can be common for the manufacture of molding parts of the mold without heat treatment; these factors will significantly reduce the time for the manufacture of equipment.

Why you should use a hot runner system?

Nowadays, for custom molding more and more often molds are made of hot runner systems, and there are reasons for this. The use of the hot runner systems has many advantages. It includes:

- Casting time costs are reduced.

- Reduced pressure in the mold.

- Improved product quality.

- Reducing the cooling time and obtaining the finished product.

- Lower the cost of the product.

Disadvantages of custom molding

There are also disadvantages of using hot runner systems

- They are expensive.

- Difficulty in servicing

- There are problems if you work on secondary material.

You can read more about hot runner systems and their use in our articles regarding custom molding further aspects.

Role of thermostatic structure in custom molding

The general information about hot channel systems. Res-forms with a hot runner system for processing thermoplastics. Secondly, the thermostatic structure of the mold must create the correct distribution of the thermal sides of the molding levels of the mold and be separate to reduce the time spent on the manufacture of the part.

Working process of 3D machines

The final work of the designer to develop a mold will be a 3-d model of the form, and a set of technical documentation. Moreover, the 3-D example of the forming planes made by the designer is common for the writing of programs and processing of surfaces of metal on the ChPU machine.

At the end of the creation of products of the custom molding in accordance with the design documentation is assembled, also prepared for testing the mold. In addition, after installing the mold on the mold, testing the mold, the task of testing. To collect information for future changes and corrections of surfaces, gutter, and ventilation systems, after these actions, the mold comes into operation.

Injection molding- last stage of custom molding

The final stage of manufacturing the part – Injection molding. Also, at this stage, it is important to adjust the process of casting plastic parts under pressure. Here you will find a special guide for plastics processing.

Setting up the process of casting plastic parts under pressure. Also, the preparation of the process of casting plastic parts under pressure involves a sequence of certain actions, as we wrote earlier in the article.

How is custom molding use in medicine and pharmaceuticals?

In the medical and pharmaceutical industries, the quality of equipment of custom molding is paramount. Moreover, it gives the health and safety, responsibility, and full traceability of the parts production process – from design to final inspection.

It is critical to choose the manufacturer of medical equipment parts and components: standardized parts for molds and dies, as well as tools care and efficiency of the equipment.