What is Injection molding?

What are the advantages of injection molding? The essence of this method lies in the fact that the molten metal is fed into a steel split mold under pressure. The working pressure on the melt is carried out directly by compressed air (gas) or by a piston, which moves under the action of compressed air (gas), emulsion, or oil.

The pressure can reach several hundred atmospheres, which ensures good filling of the mold and the production of castings of the 3-5th accuracy class and with a surface roughness corresponding to the 5-8th class. This provides great performance.

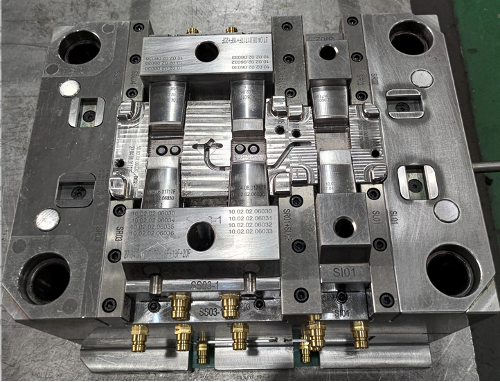

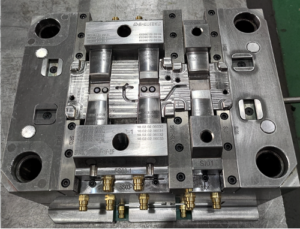

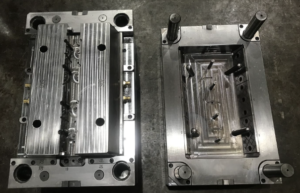

Injection molding is carried out on compressor and piston machines. Piston machines are made with vertical and horizontal pressing chambers. Chambers can be cold or hot.

The scheme of injection molding on a machine with a vertical chamber is as follows. Melt 2 is poured with a measuring spoon into the pressing chamber 3.

Moreover, the upper piston 1, descending, exerts great pressure on a portion of the melt, which transfers pressure to the lower piston 8. The piston, moving, open the gate channel 11, through which the melt fills the mold cavity.

The procedure of molding machine

a – with a cold vertical pressing chamber,

b – with a cold horizontal pressing chamber;

c – position before pouring,

d – during pouring,

e – after pouring

Moreover, the mold consists of two half-molds 4 and 5. After the melt solidifies, the half-mold 4 moves aside, and the casting 7 together with the sprue 10 pushes out by pushers 6. Excess metal 9, which has not entered the mold cavity, pushes out of the chamber by piston 8 and goes to the smelter.

Injection molding on a machine with horizontal chamber proceeds in the same sequence.

What are the advantages of injection molding?

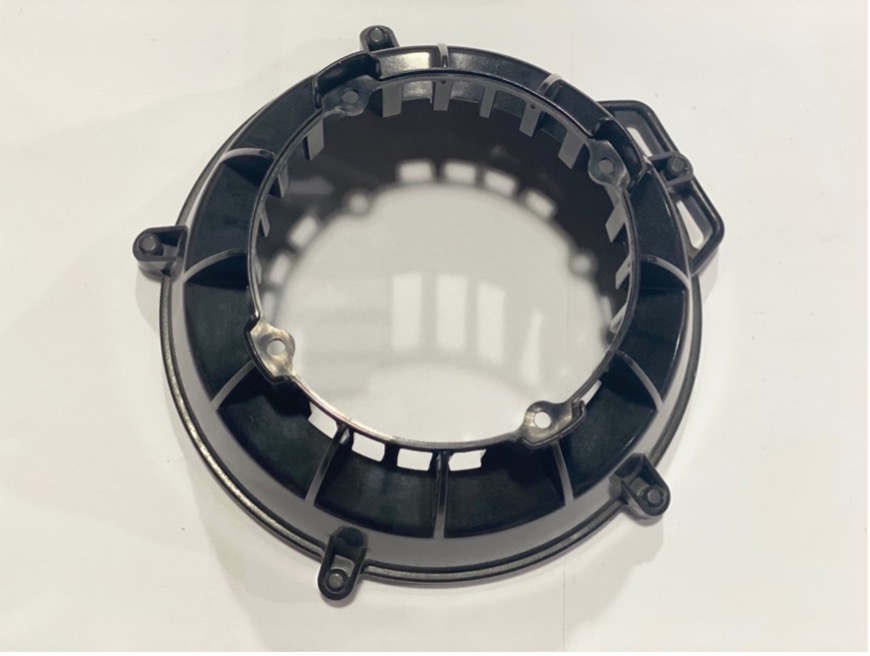

Injection molding allows you to solve one of the most important tasks of foundry production: to bring the dimensions of the casting as close as possible to the dimensions of the finished part.

Moreover, castings obtained in metal molds have a clean and smooth surface, which significantly reduces the surface finish of parts (grinding, polishing, etc.). This method uses to cast critical parts with thin walls and complex configurations.

In addition, injection molding is used to connect several parts or to obtain castings with fittings from other metals. Castings obtained by injection molding have a fine-grained structure and high mechanical properties.

The most advanced methods for manufacturing castings

What are the advantages of injection molding? It is also economically advantageous that a large number of castings can produce in a single mold in a short time. The high productivity of this casting method and the minimum allowances reduce the cost of production both in the foundry and in the machine shops.

In addition, injection molding eliminates the use of sand, so sanitary production conditions are better than in conventional foundries.

Moreover, on the other hand, injection molding is a complex technological process that requires knowledge of alloy metallurgy, casting technology, special knowledge of tool production in the manufacture of molds, and, finally, mechanics in the operation of injection molding machines.

Injection molding has some drawbacks

Injection molding has some drawbacks, such as the appearance of small air pockets (porosity) in castings. The air in the cavity of the mold does not have time to completely go out and partially mixes with the melt.

The gases dissolved in the metal do not have time to leave the casting; due to the porosity of the casting, it is impossible to heat treat it, since swellings appear when heated. Moreover, it is difficult, and sometimes impossible, to cast a part with an undercut and internal cavity in this way.

The machines and molds that exist in modern production are suitable only for the manufacture of castings from alloys with a melting point below 1000 ° C. Special experimental casting machines and molds have been made for casting steel.

Die casting can produce castings, not from all alloys

The most suitable are zinc alloys, some aluminum, and brass. Moreover, it is more difficult to obtain parts from steel and cast iron in this way. Bronze parts are not cast under pressure.

The high cost of equipment and molds makes it not always profitable to produce small batches of castings by injection molding, so the injection molding method is widely used in serial and mass production.

The 6 advantages of plastic injection molding

Injection molding allows the production of large quantities of plastic products and components in a short time. Moreover, it guarantees the dimensional repeatability of the pieces and reduces production costs thanks to the automation of the production process.

What are the advantages of injection molding? The molding of plastic materials is one of the most widespread techniques in the transformation processes of plastic materials.

It is a procedure whereby the techno plastic material melts and injects at high pressure inside the closed molds. It opens once the material has solidified and the product is ready.

Moreover, the wide diffusion of this technique can explain by its important advantages. It brings in terms of production efficiency and cost reduction.

But that’s not all: there are numerous other advantages of plastic injection molding that make this technique a viable solution for the production of plastic components.

It is precisely for this reason that we use injection molding of plastic materials to provide its customers with quality products that best meet the needs of various companies.

The 6 advantages of plastic injection molding.

Injection molding of plastic materials means obtaining large quantities of products in a short time. Moreover, this advantage accompanies by the consequent possibility of reducing production costs. Thanks to the automation of the entire procedure.

Production of complex design components

The versatility of injection molding involves, among other advantages. The possibility of obtaining parts with complex geometries is impossible to obtain with different techniques. In this way, injection molding makes it possible to respond to any need, making possible a high degree of customization of the products.

Moreover, the experience and competence of the supplier certainly contribute to this advantage.

The strength and stability of the pieces produced

Thanks to their stability, the plastic components have excellent durability over time. Thus, contributing to the quality of the final product itself.